Je to veľmi bežný kov v našom každodennom živote. Skutočne, výrobci aluminírových plátov ho vyrábajú na použitie všade na rôznych veciach, ktoré dotýkame každý deň. Je skutočne veľmi ľahká, ale zároveň je extrémne silná a odolná pred rdzením. Dôvody týchto úžasných vlastností sú také, že sa aluminírový plát používa na mnoho vecí: lietadlá; kuchyňské nádobí ako hrnce a pánve; dokonca aj stavebné materiály, ktoré používame v domoch a kanceláriách. Určite ste už počuli o jeho vlastnostiach takmer nekonečnekrát. No, Napadlo vás niekedy, ako my robíme hliníkový plech ? Učte sa, ako sa vyrobí tu.

Hliníkový plech

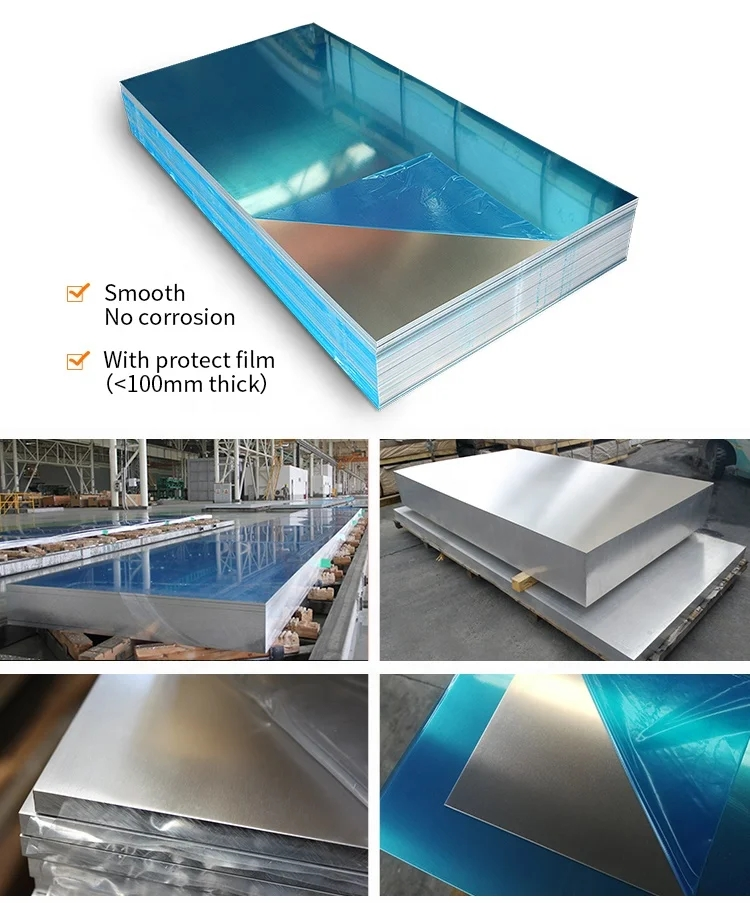

Aluminiumová deska predstavuje vysoko kvalitné aluminiumové desky spoločnosti Runhai, známeho výrobcu aluminiumových produktov. Tieto desky sú presné a spoľahlivé a ponúkajú sa vo viacerých slitinách, vrátane 6061 a 7075, ako aj iných slitín navrhnutých pre pevnosť, lehkosť a ochranu pred koroziou. Vyrábajú sa pomocou techník horeneho a studeneho valenia na zvýšenie rovnomernosti hrúbky a kvality povrchu. Danky ich vlastnostiam sa tieto desky používajú v rôznych odvetviach, ako sú letecký priemysel, automobilový priemysel, stavebnictvo, námorné dopravné prostriedky a ďalšie, kde je potrebná vysoká výkonnosť a trvanlivosť. Spoločnosť Runhai tiež praktizuje udržateľný prístup k podnikaniu, keďže aluminiumové produkty majú vysokú recyklovateľnosť a efektívnosť a environmentálne otázky sú kľúčovými aspektmi pre priemysel.

Špecifikácie spracovania

Keď odstránime oxid hliníka, musíme ho potom vložiť do veľmi horkého pečiaru. Táto tepelná úprava redukuje oxid hliníka na lesklý drôt. Tento proces nazývame „tavenie“. Hliníková kovina sa najskôr vyrobí vo forme obrovských blokov a nazýva sa ingoty. Tieto ingoty môžu byť následne prevádzané na rovné listy pomocou valenia alebo tlačenia – lepšie ich poznáte ako hliníkový plech .

V súvislosti s hliníkovým plechom je ďalší proces ohrievanie ingotov, aby boli mäkšie a jednoduchšie na obrábanie. Po ohriatí sa ingoty valia dvoma veľmi veľkými valcami. Tieto valce ich stlačujú a zmáčknu do tenkých pliat. Medzera medzi valcami je prispôsobiteľná na zmenu hrúbky týchto pliat. Teraz sú tyto pliaty rozložené na ochlodenie a následne rozdelené na veľkosti podľa ich použitia.

Aluminiová deska je materiál, ktorý používame denne, prečo hovoríte, že výroba a technológia spracovania v aluminiovej oblasti ponúkajú toľko zaujímavé veci? Aluminium je extrémne reaktívny materiál a nie je stabilné v prírodnom prostredí. navyše môže byť príliš reaktívne na stavebnú úžitok. Avšak, práve vlastnosti aluminia, ktoré predstavujú výzvy pri jeho manipulácii a spracovaní, sú typicky tie, ktoré ho robia atraktívnym v širokom spektre produktov/aplikácií.

Musíme poznať o rôznych druhoch hliníkových plátov, aby sme mohli vybrať ten správny, ktorý spĺňa naše požiadavky. Existujú rôzne triedy hliníkových plátov, ktoré majú štyričíslove označenie, ktoré to ukazuje. Prvé číslo v triede uvádza, ktoré základné spojové kovy boli zmiešané do hliníka. Druhé číslo popisuje, či bola oceľ nejakou formou upravená. Prvé dve čísla identifikujú spoj a stredné číslo nám hovorí, ku ktorému rade hliníka patrí (a ešte konkrétneji pri identifikácii presnej sústavy). Posledné dve čísla ukazujú, aký percentuálne množstvo toho konkrétnego prísadu bolo použité.

Aluminová deska: aluminový list je rovnaký ako farba, ale má rôznu kvalitu alebo úlohu. Napríklad populárna voľba je aluminová deska 6061, ktorá je veľmi pevná a odolná, čo ju robí dokonalou pre náročné úlohy. Aluminová deska 3003 sa ponúka na práce, ktoré vyžadujú tvarenie alebo spájanie. Naši klienti si môžu vybrať z mnohých rozmerov aluminovej desky, ktoré sú najvhodnejšie pre ich prácu s Runhai.

Existuje mnoho spôsobov výroby hliníkové pláty keď zvážime, ako boli vyrobené. Jeden bežný proces je teplé valenie. Pri teplom valení sú ingoty znovu prerastené a valené, kým sú ešte horečkate. Táto metóda prispieva k vytvoreniu rovnomerného hrúbku cez tenké produkty. Studené valenie ďalej spracováva desky tak, že ich ochladí a potom ešte raz valí, aby boli ťažšie.

Aluminiumové pláty sa tiež správajú inak, keď sú zaobchádzané inými technikami. Jedným typom tohto procesu je známy ako zvykovanie. Následne je placka preradena na veľmi vysokú teplotu predtým, než je pomaly ochladená počas zvykovania. Je potrebné uvoľniť aluminiumovú placku, aby ju bolo možné tvarovať a formovať. Zchladzovanie je ďalším spôsobom, akým sa vyrobujú letecké šrouby. Zchladzovanie sa vykonáva na rýchle ochladzovanie placky, čo spôsobí, že sa stane tvrdšou a kruchou.

Záver

Zhrnutím, výroba a spracovanie aluminiumovej placky je tiež zložitý proces. Existujú rôzne typy aluminiumových platiek, ktoré užívateľom uľahčia vybrať, ktorý je najlepší typ špecifikovaný práve pre ich potreby a pochopenie týchto vlastností im pomôže vybrať správne. Výrobné podniky sľubujú, že domáce lodné aluminiumové placky sú najlepšej kvality. Používame topnotné stroje a metódy, aby sme sa isti, že vždy dodávame prácu vysokého štandardu.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN