RUNHAI STEEL

Your Reliable Steel SupplierRunhai steel is not only a professional steel supplier, but also your trustworthy partner in China. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase. Regarding long-term cooperation or large orders, you can contact us for additional discounts.

Enjoy Bulk Order DiscountsFOUR REASONS TOCHOOSE US

-

AAA Level

Credit Steel Supplier

Gold Certified Merchant

-

20+

Have our own R&D team

Large inventory Warehouses

-

Support

Three-party Inspection

-

Large Order

Preferential Policies

Get in touch

Листовая плита из высокомарганцевой стали Mn15Cr1

Листовая плита из высокомарганцевой стали Mn15Cr1

ВИДЕО ПРОДУКТА

Параметр продукта

| Элементы | Листовая плита из высокомарганцевой стали Mn15Cr1 | ||||

| Стандарт | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN и т.д. | ||||

| Техника | Горяче-холодные прокатные | ||||

| Длина | 4м-12м или по требованию | ||||

| Ширина | 0.5м-3м или по требованию | ||||

| Толщина | 0.12мм-40мм или по требованию | ||||

| Поверхность Обработка |

Очистка, пескоструйная обработка и окраска согласно требованиям клиента | В соответствии с требованиями клиента | |||

| Толщина Погрешность |

±0.1мм | ±0,15 мм | ±0.1мм | ±0,15 мм | ±0.1мм |

| Материал |

NM450L,NM450A,NM600,NM400,NM400L,NM400A, NM500A,NM500,NM360L, NM360,NM550,NM450 NR360, NR400, MITTA 400F, MITTA 450F, MITTA 500F Хардокс400, Хардокс450, Хардокс500, Хардокс550, Хардокс600, SB-40, SB- 45, SB-50 |

Q345, Q345A,, Q345B, Q345C , Q345D, Q345E, Q235BHC340LA, HC380LA, HC420LA B340LA, B410LA 15CRMO, 12Cr1MoV, 20CR, 40CR, 65MN A709GR50 |

Q245R,Q345R,Q370R 15CrMoR,15MnNiDR,15Mo3,15CrMoG 09MnNiDR,12MnNiVR, 13MnNiMoR, Gr70,18MnMoNbR,19Mn612Cr2Mo1R,12Cr1MoVR, 12CrMo1R,14Cr1MoR |

NVA,NVD,A,A32,,A36,AH32,AH36 ,B,16MnL Q235,Q235BEH32,EH36 CCS-A,CCS- B,CCSA,CCSB,CCS,CCSD,CCSE D32,D36,DH32,DH36, GL-B,GL-D,GL-E, E32,E36 |

09CuPCrNi-A,09CuP, 09CuPCrNiA, 09CrCuSb Q355NH, Q460NH,Q345GNHL,Q345GNHL, Q355GNH,Q345GNH,Q295NH, Q295NH,Q295NH,Q310GNH,Q345NH, Q235NH, Q500NH,Q235GNH,Q550NH,Q265GNH,Q295GNH,Q450NQR1 |

| Применение |

Широко используется в горнодобывающей промышленности машиностроении, оборудовании для охраны окружающей среды, оборудовании для производства цемента, строительном оборудовании и т.д., так как обладает высокой износостойкостью и т.д. |

Используется в деталях машин и строительных компонентах, измерительных инструменты и т.д. |

Используется в инструментальной стали, стали цементации и сталь подшипников и т.д. |

Используется для изготовления корпуса корабля, палуб и т.д. |

Также может использоваться для пола панели, контейнеры, трубы электростанций, железнодорожное строительство и другие наружные стали, например, крупная наружная скульптурная сталь и т.д. |

| экспорт Упаковка |

Упаковано в водонепроницаемую бумагу и стальную полосу. Стандартный экспортный пакет. Костюм для всех видов транспорта или по требованию. |

||||

| сертификация | CE, ISO,SGS, и т.д. | ||||

| MOQ | 25 тонн | ||||

| Срок исполнения | Обычно 7 дней, в зависимости от количества | ||||

| Оплата | T/T, L/C, Western Union, Paypal, DP и т.д. | ||||

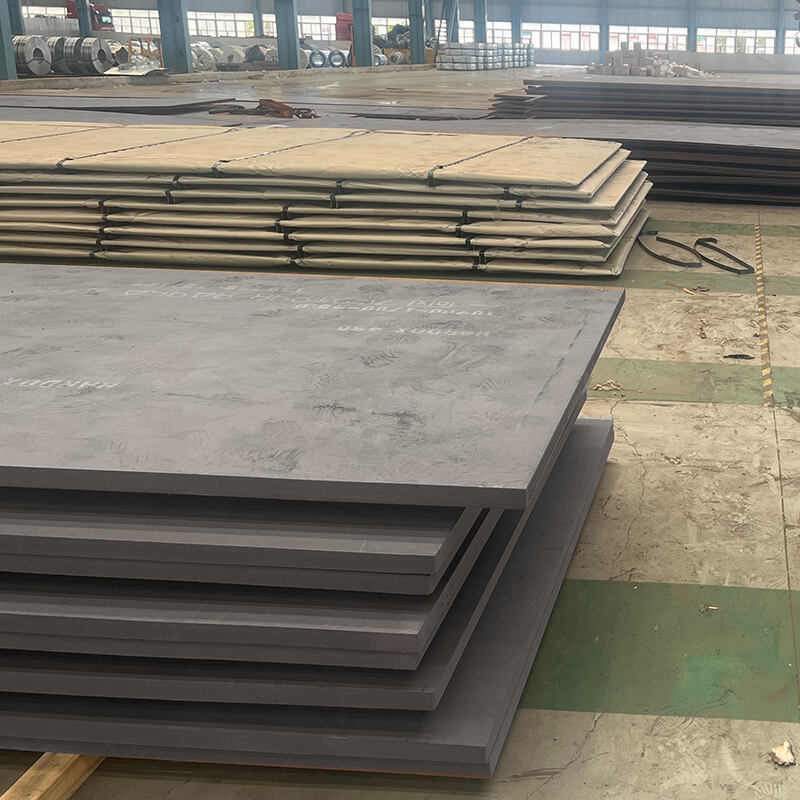

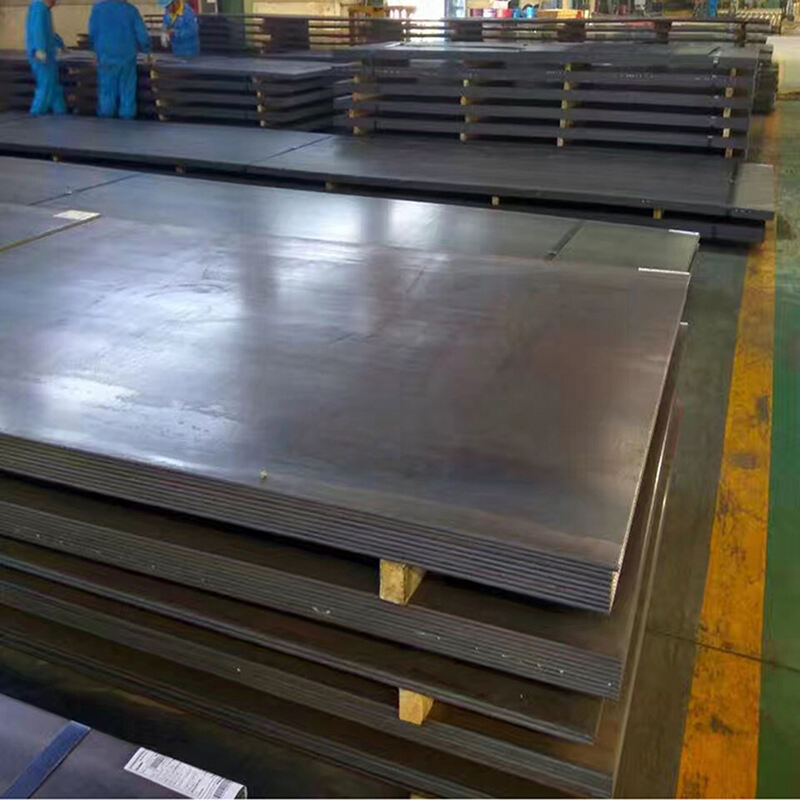

Показ продукта

Сталь с высоким содержанием марганца, износостойкая

Mn15Cr1, называемая марганец 15 хром 1, является более качественной высокомарганцевой износостойкой сталью, чем Mn13.

Mn15Cr1 основана на Mn13 Сталь, устойчивая к износу для дальнейшего улучшения содержания углерода и марганца, при этом добавляя хром и различные редкие металлы. Повышение содержания углерода в материале может улучшить износостойкость сплава, увеличение содержания марганца может повысить твердую растворимость сплава и ударную вязкость сверхвысокомарганцевой стали. После добавления элемента хрома в высокомарганцевую сталь образуется хромовый сплав цементит (Fe, Cr) 3C, который более стабилен, чем цементит Fe3C. Сплавной цементит распределяется в стали, что обеспечивает распределение дисперсных карбидных твёрдых точек в высокоупругом аустенитном матриксе, тем самым повышая эффект закалки и усиливая износостойкость. После соответствующего увеличения содержания углерода, марганца и хрома начальная твёрдость сверхвысокомарганцевой стали после водной закалки выше, чем у обычной высокомарганцевой стали, и срок службы материала до образования слоя рабочей закалки увеличивается на начальном этапе использования материала, а также значительно возрастает скорость рабочей закалки.

Особенности продукта

① ВЫСОКАЯ ПРОИЗВОДИТЕЛЬНОСТЬ

Гладкая поверхность, отличная коррозионная стойкость и высокая теплостойкость, достаточный слой цинка

② ВЫСОКОЕ КАЧЕСТВО

Лучшие сырьевые материалы для производства, передовые технологии и тщательная система контроля

③ НАСТРОЙКА ПОВЕРХНОСТИ

Идеальная покраска и красивый внешний вид, настройте под свои разные потребности

У нас есть строгая система обнаружения для поддержки трехстороннего обнаружения

| Химический состав | ||||||

| Стальной сорт | C | Да, да. | Mn | Р | s | Als |

| Класс AH36 | ≤0.18 | ≤ 0,50 | 0.9-1.6 | ≤ 0,035 | ≤ 0,035 | ≥0.015 |

| Класс DH36 | ≤0.18 | ≤ 0,50 | 0.9-1.6 | ≤ 0,035 | ≤ 0,035 | ≥0.015 |

| Класс EH36 | ≤0.18 | ≤ 0,50 | 0.9-1.6 | ≤ 0,035 | ≤ 0,035 | 20.015 |

| Класс FH36 | ≤0.18 | ≤ 0,50 | 0.9-1.6 | ≤ 0,035 | ≤ 0,035 | 20.015 |

| Механические свойства | |||||||

|

Сталь Grade |

урожайность точка/МПа A |

Растяжение пункт /MPa |

Длина/ % |

Температура/° C |

ударный тест типа V | ||

| Akv/Дж | |||||||

| ≤50ММ | 50-70мм |

70- 100mm |

|||||

|

Grade AH36 |

≥355 | 490-630 | ≥21 | 0 | 34/24 | 41/27 | 50/34 |

|

Grade DH36 |

≥355 | 490-630 | ≥21 | -20 | 34/24 | 41/27 | 50/34 |

|

Grade EH36 |

≥355 | 490-630 | ≥21 | -40 | 34/24 | 41/27 | 50/34 |

|

Grade FH36 |

≥355 | 490-630 | ≥21 | -60 | 34/24 | 41/27 | 50/34 |

Технологический процесс изготовления из углеродистой стали:

Плавка углеродистой стали обычно осуществляется в конвертере и мартеновской печи. Конвертеры, как правило, плавят обычную углеродистую сталь, тогда как мартеновские печи плавят различные виды высококачественной стали. Технология кислородного верхнего продувания конвертера развивается стремительно и может заменить мартеновскую печь. Очищенная жидкая сталь заливается в слитковую форму для получения различных слитков. После того как слиток подвергается ковке или прокатке, он обрабатывается в листы, полосы, прутки и профили различного сечения. Углеродистая сталь обычно используется непосредственно в горячекатаном состоянии. При использовании для изготовления инструментов и различных деталей машин ей необходимо подвергать термической обработке в соответствии с требованиями использования; Что касается сталелитых отливок, большинство из них подвергается термообработке.

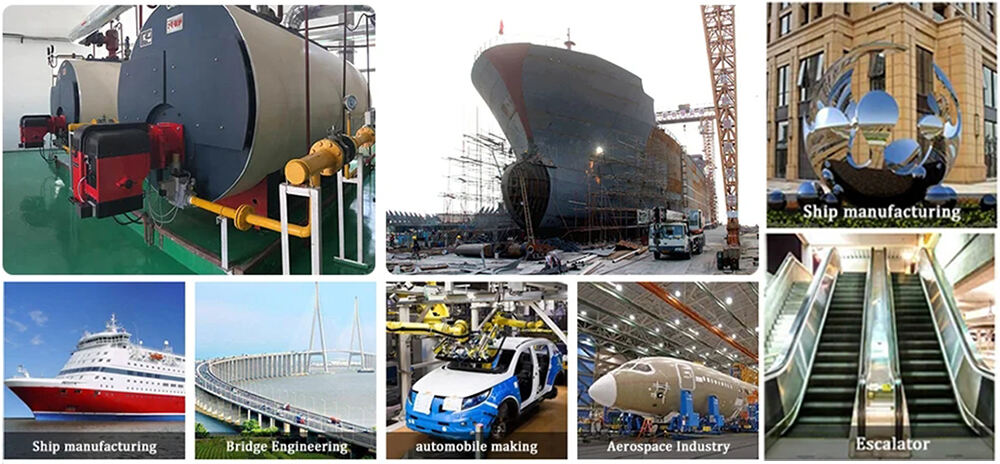

Применение

Применение углеродистой стали

1. Строительная отрасль: Углеродистые стальные плиты часто используются при изготовлении строительных конструкций, таких как стальные каркасы, балки и т.д. Благодаря высокой прочности и пластичности стальной плиты, она может выдерживать большие нагрузки, поэтому широко применяется в строительстве.

2. Производство автомобилей: Углеродистая стальная плита является важным материалом для производства кузова и рамы автомобиля. Она обладает хорошей пластичностью и свариваемостью, что удовлетворяет требованиям автомобильного производства.

3. Производство бытовой техники: Углеродистые стальные плиты часто используются в производстве бытовой техники, такой как холодильники и стиральные машины. Через процесс штамповки углеродистую стальную плиту можно превратить в детали различных форм, чтобы удовлетворить потребности бытовой техники.

4. Судостроение: Листы из углеродистой стали также широко используются в судостроении. Благодаря хорошей пластичности и свариваемости углеродистой стали, они соответствуют требованиям корабельной конструкции.

5. В других областях листы из углеродистой стали также широко применяются в машиностроении, нефтеперерабатывающей и металлургической промышленности.

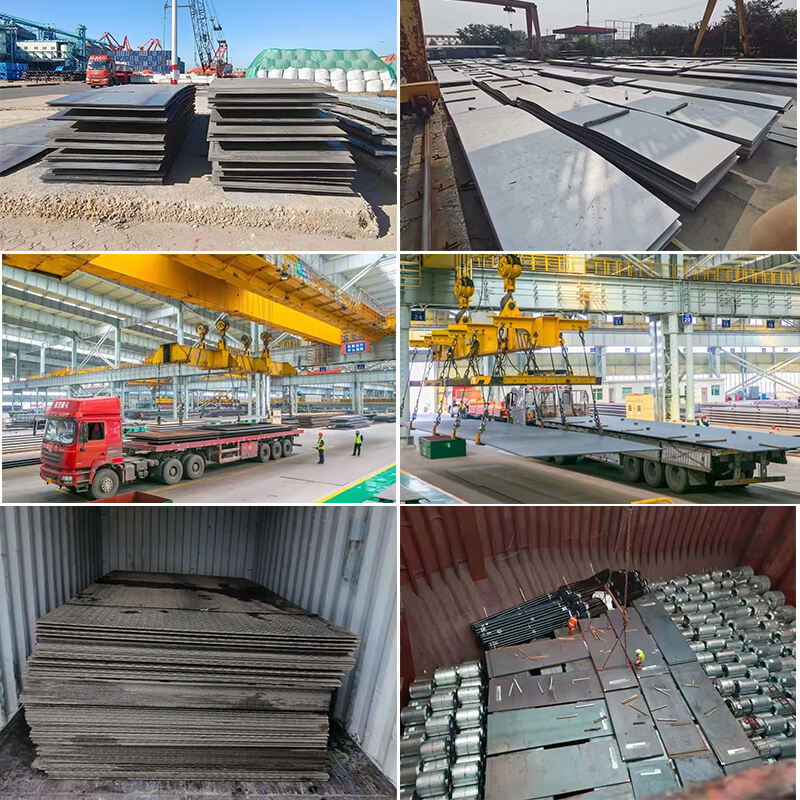

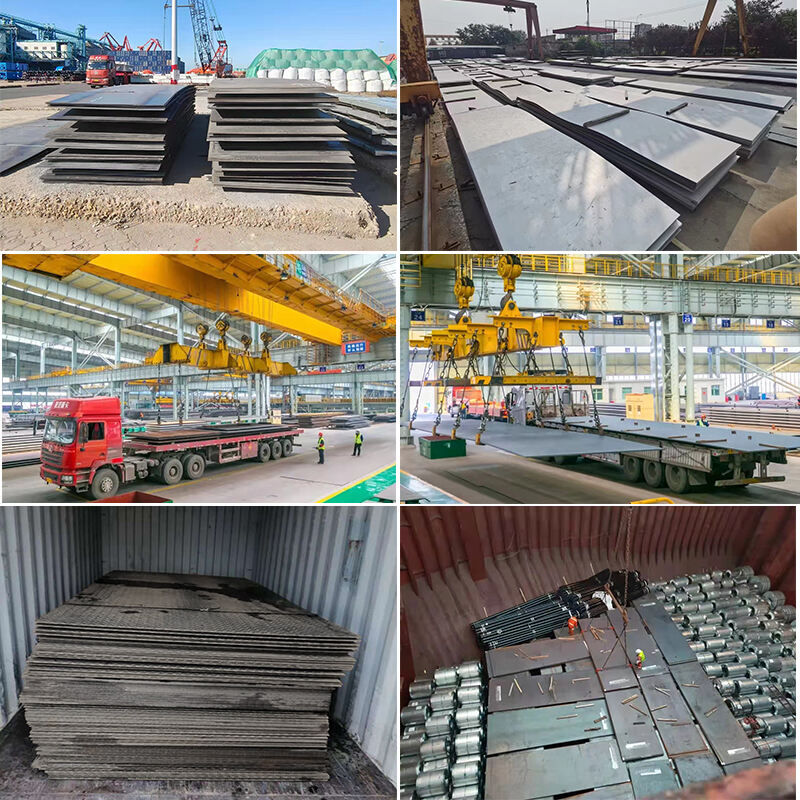

Упаковка и доставка

20ft GP: 5.8m(длина) x 2.13m(ширина) x 2.18m(высота)

40ft GP: 11.8m(длина) x 2.13m(ширина) x 2.18m(высота)

40ft HG: 11.8m(длина) x 2.13m(ширина) x 2.72m(высота)

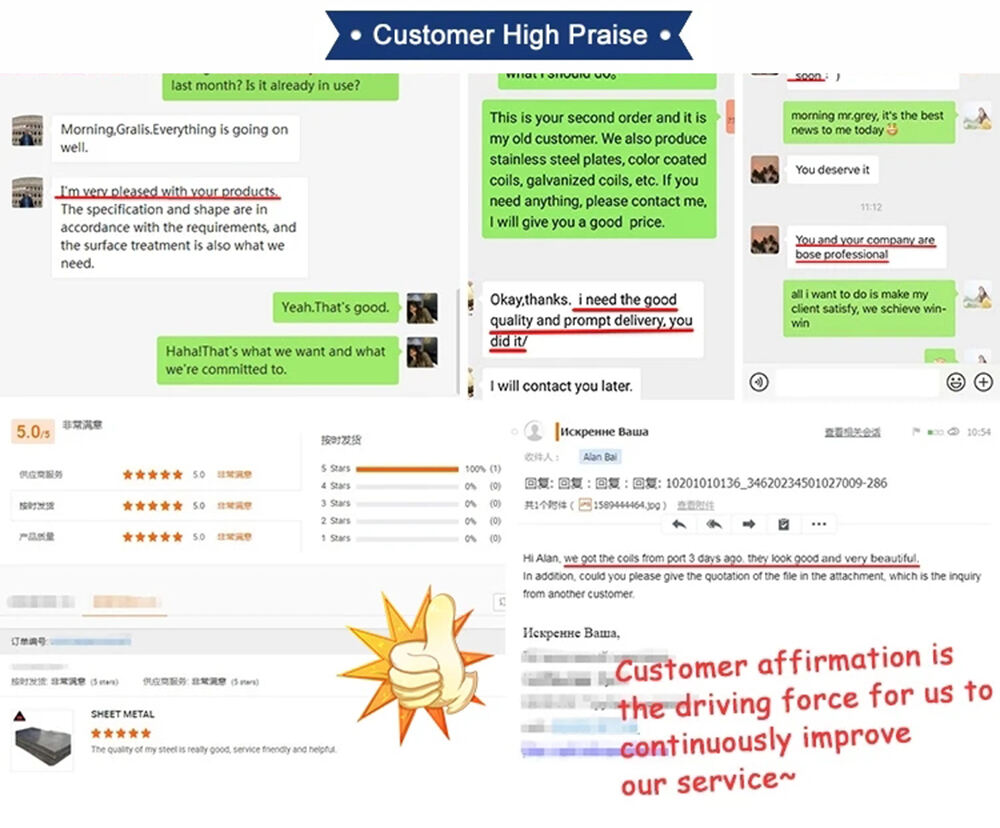

Обратная связь от клиентов

ЧАВО

В: Вы доставите товары вовремя?

A: Да, мы обещаем предоставить продукцию наилучшего качества и своевременную доставку. Честность является девизом нашей компании.

Вопрос: Вы предоставляете образцы?

О: Образец может быть предоставлен клиенту бесплатно, но стоимость курьерской доставки будет покрыта счетом клиента.

В: Вы принимаете инспекцию третьей стороны?

О: Да, абсолютно, мы принимаем.

Q: Как вы можете гарантировать качество вашей продукции?

A: Каждый продукт изготавливается сертифицированными цехами, проверяется поштучно согласно национальному стандарту качества QA/QC. Мы также можем предоставить гарантию покупателю для обеспечения качества.runhaiпоштучно согласно национальному стандарту качества QA/QC. Мы также можем выдать гарантию клиенту для обеспечения качества.

В: Как мы можем доверять вашей компании?

О: Мы специализируемся на сталелитейном бизнесе в течение многих лет, штаб-квартира расположена в Джинане, провинция Шаньдун, вы можете исследовать любые способы, любыми средствами, вы можете разместить заказ с торговой гарантией, которая может обеспечить вашу оплату.

В: Как я могу получить вашу цитату как можно скорее?

A: Электронная почта и факс будут проверены в течение 24 часов, при этомFacebook,Skype, Wechat и WhatsApp будут доступны в течение 24 часов. Пожалуйста, отправьте нам свои требования и информацию о заказе, спецификацию (марка стали, размер, количество, порт назначения), и мы很快 рассчитаем лучшую цену.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN