RUNHAI STEEL

Your Reliable Steel SupplierRunhai steel is not only a professional steel supplier, but also your trustworthy partner in China. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase. Regarding long-term cooperation or large orders, you can contact us for additional discounts.

Enjoy Bulk Order DiscountsFOUR REASONS TOCHOOSE US

-

AAA Level

Credit Steel Supplier

Gold Certified Merchant

-

20+

Have our own R&D team

Large inventory Warehouses

-

Support

Three-party Inspection

-

Large Order

Preferential Policies

Get in touch

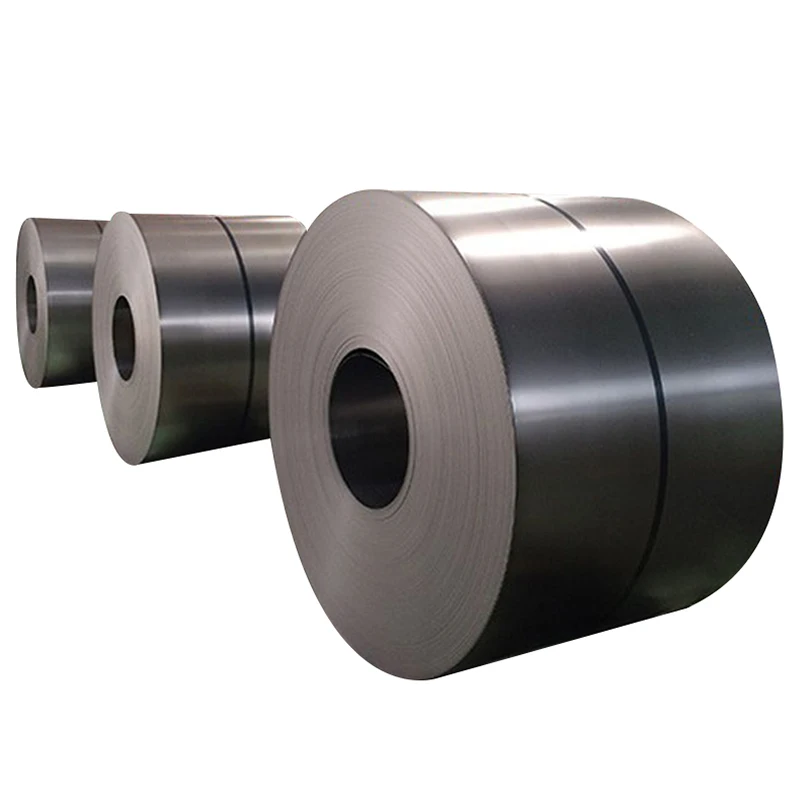

Aço silício 2

O aço silício é um material de liga ferrossilício de extremamente baixo teor de carbono, com conteúdo de silício entre 0,5% e 4,5%. O aço silício possui as características de alta permeabilidade magnética, baixa coercitividade e grande resistividade. De acordo com diferentes processos de produção, ele pode ser dividido em aço silício laminado a quente e aço silício laminado a frio.

Vídeo do Produto

Descrição

O aço silício, como um aço comumente utilizado, tem uma ampla gama de aplicações e é amplamente usado na indústria. Ele pode aumentar a indução magnética projetada, reduzir o tamanho do núcleo de ferro e o peso. Pode economizar aço silício, fios, materiais de isolamento, materiais estruturais, etc., o que não apenas reduz as perdas e o custo de fabricação de motores e transformadores, mas também facilita a montagem e o transporte. Ele possui características de alta permeabilidade, baixa coercitividade e grande coeficiente de resistência, portanto, as perdas por histerese e corrente de Foucault são pequenas. É usado principalmente como material magnético em motores, transformadores, eletrodomésticos e instrumentos elétricos.

Parâmetro do Produto

| Nome do Produto | Aço silício |

| Categoria | Aço Elétrico Orientado a Grão; Aço elétrico não orientado |

| Grau | Aço Elétrico Orientado a Grão: JIS: 23R090, 27R095, 30G130 EN: M85-23Pb, M090-27Pb, M130-30S Aço Elétrico Não Orientado: JIS: 35A210, 50A250, 65A310 ASTM : 36F145, 47F165, 64F200 EN: M210-35A, M250-50A, M310-65A\ |

| Padrão | B23G110, B27G120, B35G155, B23R080-B27R095, ETC |

| Espessura | 0,23mm-0,35mm ou conforme solicitado |

| Largura | 20mm-1250mm ou conforme solicitado |

| Comprimento | em bobina ou conforme necessário |

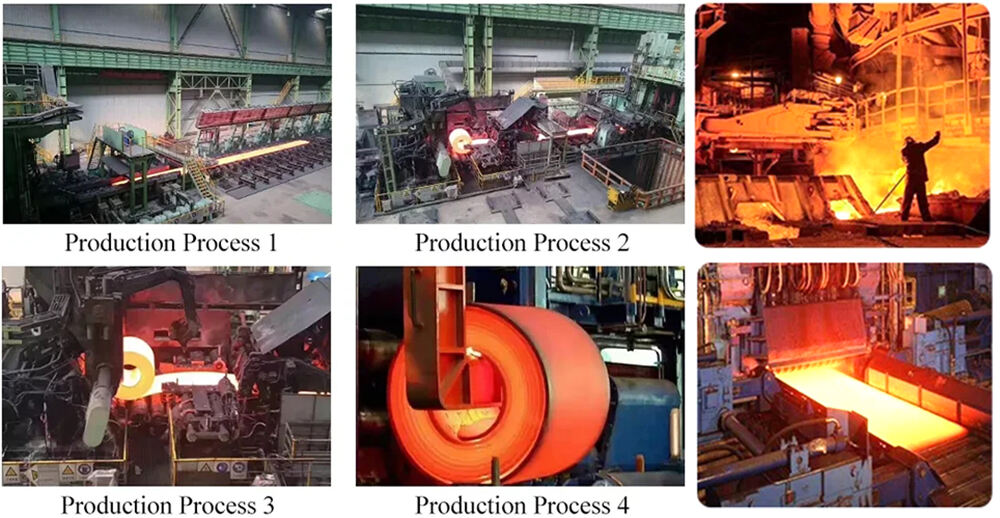

| Técnica | Laminação a Frio |

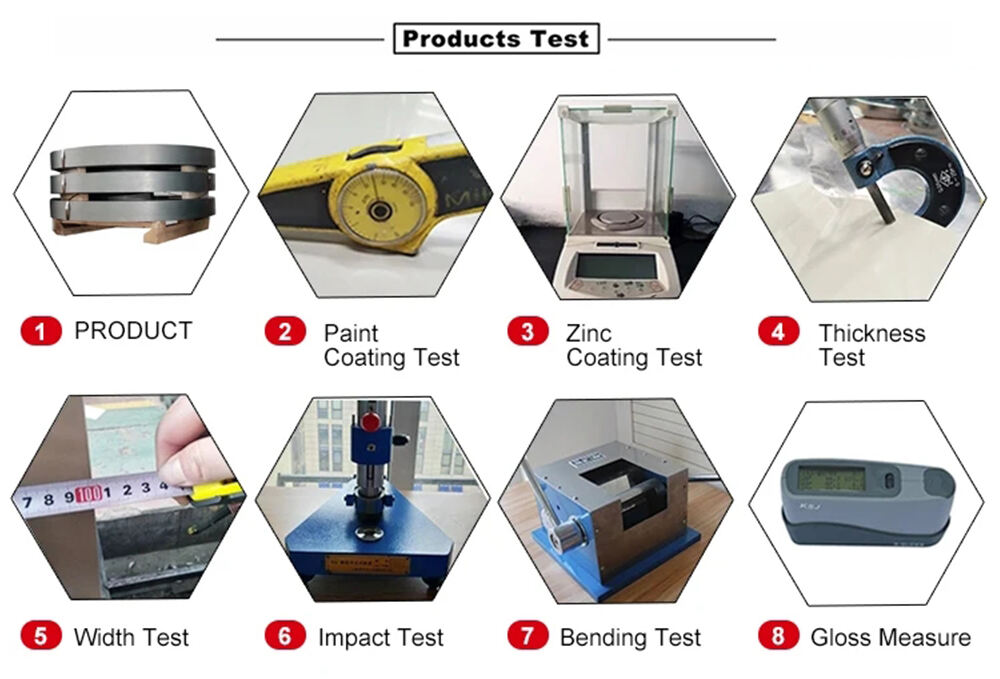

| Certificação | CE,ISO,SGS,ETC |

| Quantidade mínima | 25 toneladas |

| Pagamento | TT, LC, ETC |

| tEMPO DE ENTREGA | Normalmente 7 dias, dependendo da quantidade |

| Pacote | Embalo padrão marítimo (caixas de madeira, embalagem e outros tipos) ou conforme os requisitos do cliente. |

| Aplicação | Usado amplamente em transformadores, geradores, diversos motores domésticos e micro-motores, etc. |

| Tipo | Grau | Nominal Espessura |

Teórico Densidade |

Perda máxima de núcleo | Indução mínima | Laminação Mín. Fator |

| mm | kg/dm3 | W/kg | T | % | ||

| Convencional | 23Q110 | 0.23 | 7.65 | 1.10 | 1.82 | 94.5 |

| 23Q120 | 0.23 | 7.65 | 1.20 | 1.82 | 95.0 | |

| 27Q120 | 0.27 | 7.65 | 1.20 | 1.82 | 95.5 | |

| 27Q130 | 0.27 | 7.65 | 1.30 | 1.82 | 96.0 | |

| 30Q120 | 0.30 | 7.65 | 1.20 | 1.82 | 96.0 | |

| 30Q130 | 0.30 | 7.65 | 1.30 | 1.82 | 96.0 | |

| 35Q135 | 0.35 | 7.65 | 1.35 | 1.82 | 96.5 | |

| 35Q145 | 0.35 | 7.65 | 1.45 | 1.82 | 96.5 | |

| 35Q155 | 0.35 | 7.65 | 1.55 | 1.82 | 96.5 | |

| Alto Indução |

18QG085 | 0.18 | 7.65 | 0.85 | 1.86 | 92.0 |

| 18QG095 | 0.18 | 7.65 | 0.95 | 1.86 | 92.0 | |

| 20QG085 | 0.20 | 7.65 | 0.85 | 1.86 | 93.0 | |

| 20QG095 | 0.20 | 7.65 | 0.95 | 1.86 | 93.0 | |

| 23QG085 | 0.23 | 7.65 | 0.85 | 1.88 | 94.5 | |

| 23QG090 | 0.23 | 7.65 | 0.90 | 1.88 | 94.5 | |

| 23QG095 | 0.23 | 7.65 | 0.95 | 1.88 | 94.5 | |

| 23QG100 | 0.23 | 7.65 | 1.00 | 1.88 | 94.5 | |

| 27QG095 | 0.27 | 7.65 | 0.95 | 1.89 | 95.0 | |

| 27QG100 | 0.27 | 7.65 | 1.00 | 1.89 | 95.0 | |

| 27QG120 | 0.27 | 7.65 | 1.20 | 1.89 | 95.0 | |

| 30QG100 | 0.30 | 7.65 | 1.00 | 1.89 | 95.5 | |

| 30QG105 | 0.30 | 7.65 | 1.05 | 1.89 | 95.5 | |

| 30QG120 | 0.30 | 7.65 | 1.20 | 1.89 | 95.5 | |

| Domamin Refinado Alta Indução |

18RK070 | 0.18 | 7.65 | 0.70 | 1.86 | 92.0 |

| 18RK075 | 0.18 | 7.65 | 0.75 | 1.86 | 92.0 | |

| 18RK085 | 0.18 | 7.65 | 0.85 | 1.86 | 92.0 | |

| 20RK070 | 0.20 | 7.65 | 0.70 | 1.86 | 93.0 | |

| 20RK075 | 0.20 | 7.65 | 0.75 | 1.86 | 93.0 | |

| 20RK085 | 0.20 | 7.65 | 0.85 | 1.86 | 93.0 | |

| 23RK075 | 0.23 | 7.65 | 0.75 | 1.88 | 94.5 | |

| 23RK080 | 0.23 | 7.65 | 0.80 | 1.88 | 94.5 | |

| 23RK085 | 0.23 | 7.65 | 0.85 | 1.88 | 94.5 | |

| 23RK090 | 0.23 | 7.65 | 0.90 | 1.88 | 94.5 | |

| 23RK100 | 0.23 | 7.65 | 1.00 | 1.88 | 94.5 | |

| 27RK085 | 0.27 | 7.65 | 0.85 | 1.89 | 95.0 | |

| 27RK090 | 0.27 | 7.65 | 0.90 | 1.89 | 95.0 | |

| 27RK095 | 0.27 | 7.65 | 0.95 | 1.89 | 95.0 | |

| 27RK100 | 0.27 | 7.65 | 1.00 | 1.89 | 95.0 | |

| 27RK120 | 0.27 | 7.65 | 1.20 | 1.89 | 95.0 | |

| 30RK095 | 0.30 | 7.65 | 0.95 | 1.89 | 95.5 | |

| 30RK100 | 0.30 | 7.65 | 1.00 | 1.89 | 95.5 | |

| 30RK105 | 0.30 | 7.65 | 1.05 | 1.89 | 95.5 | |

| 30RK120 | 0.30 | 7.65 | 1.20 | 1.89 | 95.5 |

Exibição de Produtos

A diferença entre o aço silício orientado e o aço silício não orientado

Aço de silício não orientado: liga de ferrosilício com teor muito baixo de carbono. No aço deformado e recristalizado, seus grãos estão distribuídos aleatoriamente. O teor de silício da liga é de 1,5% a 3,0%, ou a soma do teor de silício e alumínio é de 1,8% a 4,0%. Os produtos geralmente são chapas ou tiras frias laminadas, que são usados principalmente para fabricar motores e geradores.

Aço siliconado orientado: Possui forte direcionalidade, o valor mais baixo de perda de ferro na direção do rolamento, a permeabilidade magnética mais alta e um valor de indução magnética mais elevado sob um campo de magnetização específico. O teor de silício do aço siliconado orientado é de cerca de 3%. Também exige um baixo teor de inclusões oxidantes no aço e deve conter certos inibidores (MnS, A1N).

Recursos do Produto

① Excelente desempenho de processamento: Dimensões de alta precisão e excelentes propriedades mecânicas facilitam o corte, a estampagem e o empilhamento por prensa de alta velocidade. Também possui boa capacidade de soldagem.

② Excelente desempenho do revestimento de isolamento: Cor uniforme, bom isolamento, alta adesão, excelente resistência ao calor e excelente desempenho de processamento.

③ TECNOLOGIA AVANÇADA: A dureza superficial é alta, para garantir excelente resistência ao desgaste e resistência ao contato, e possui plasticidade e tenacidade adequadas.

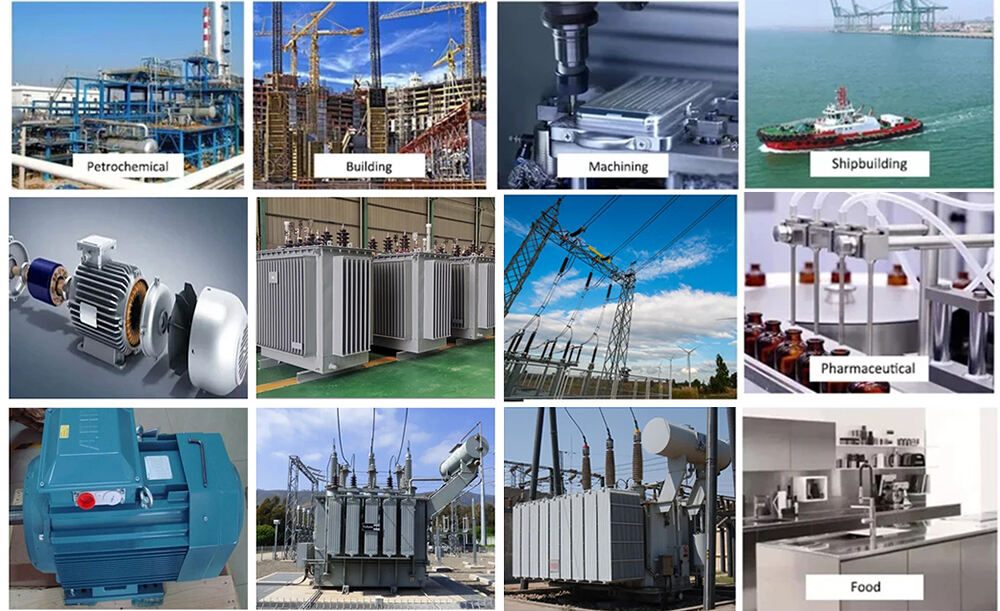

Aplicação

A aplicação de aço silício é usada nos setores de energia e telecomunicações, fabricando todos os tipos de materiais magnéticos importantes para geradores, motores, transformadores, relés, indutores mútuos e outros instrumentos elétricos.

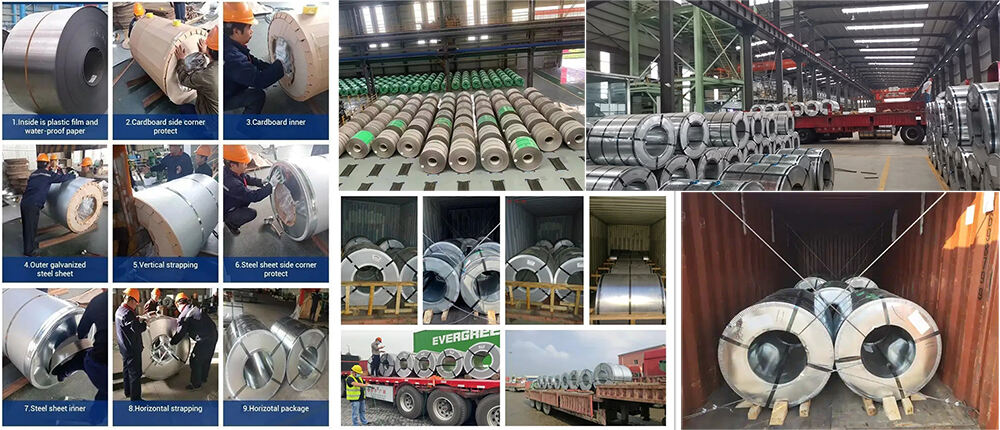

Embalagem e Entrega

Embalagem: Embalagem Padrão: filme plástico + papel impermeável + placa de aço + faixa de embalagem de aço ou conforme solicitação do cliente.

Envio: Temos cooperação de longo prazo com muitas empresas de transporte experientes e encontraremos o meio de transporte mais adequado para você.

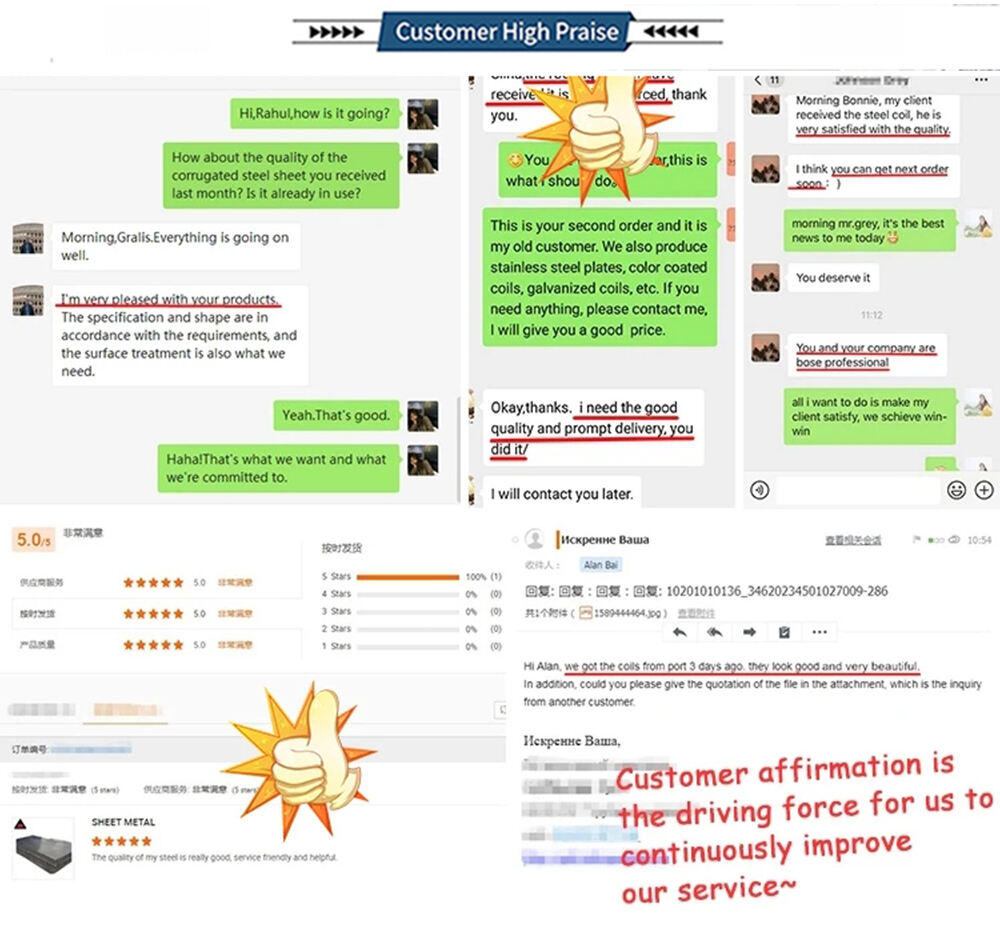

FEEDBACK DO CLIENTE

Perguntas frequentes

P: Você entregará os produtos a tempo?

R: Sim, nós prometemos fornecer produtos de melhor qualidade e entrega a tempo.Honestidade é o princípio da nossa empresa.

P: Você fornece amostras?

R: A amostra pode ser fornecida ao cliente gratuitamente, mas o frete do courier será coberto pela conta do cliente.

P: Você aceita a inspeção de terceiros?

R: Sim, absolutamente aceitamos.

P: Como pode garantir os seus produtos?

A: Cada peça dos produtos é fabricada por oficinas certificadas, inspecionada de acordo com o padrão nacional de QA/QC. Também podemos emitir a garantia ao cliente para garantir a qualidade.Runhaipeça por peça de acordo com o padrão nacional de QA/QC. Também podemos emitir a garantia ao cliente para garantir a qualidade.

P: Como podemos confiar em sua empresa?

A: Nós nos especializamos em negócios de aço há anos, a sede está localizada em Jinan, província de Shandong, você é bem-vindo a investigar de qualquer maneira, por todos os meios, você pode fazer uma encomenda com garantia comercial que poderia garantir seu pagamento.

P: Como posso obter a sua cotação o mais rapidamente possível?

A: O e-mail e o fax serão verificados dentro de 24 horas, enquanto isso, oFacebook,Skype, Wechat e WhatsApp estarão online 24 horas por dia. Por favor, envie-nos suas necessidades e informações de pedido, especificação (tipo de aço, tamanho, quantidade, porto de destino), calcularemos o melhor preço o mais rápido possível.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN