RUNHAI STEEL

Your Reliable Steel SupplierRunhai steel is not only a professional steel supplier, but also your trustworthy partner in China. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase. Regarding long-term cooperation or large orders, you can contact us for additional discounts.

Enjoy Bulk Order DiscountsFOUR REASONS TOCHOOSE US

-

AAA Level

Credit Steel Supplier

Gold Certified Merchant

-

20+

Have our own R&D team

Large inventory Warehouses

-

Support

Three-party Inspection

-

Large Order

Preferential Policies

Get in touch

製品ビデオ

製品パラメータ

| 製品名 | チタングレード9プレート |

| 等級 | ニッケル: ニッケル200/201/205 ハステロイ:ハステロイB/-2/B-3/C22/C-4/S/C276/C-2000/G-35/G-30/X/N/g ハステロイ B/UNS N10001, ハステロイ B-2 / UNS N10665 / DIN W.Nr. 2.4617, ハステロイ C, ハステロイ C-4/ UNS N06455 / DIN W. Nr. 2.4610, ハステロイ C-22 / UNS N06022 / DIN W. Nr. 2.4602, ハステロイ C-276 / UNS N10276/ DIN W. Nr. 2.4819, ハステロイ X / UNS N06002 / DIN W. Nr. 2.4665 ヘインズ: ヘインズ 230/556/188 インコネル:インコネル 600/601/602CA/617/625/713/718/738/X-750, カーペンター 20 インコネル 718 / UNS N07718 / DIN W. Nr. 2.4668, インコネル 601/ UNS Nr.2.4669, インコネル 600 / UNS N06600 / DIN W. Nr. 2.4816 インコロイ: インコロイ 800/800H/800HT/825/925/926; モネル:モネル 400/K500/R405; など。 |

| 標準 | GB、AISI、ASTM、DIN、EN、SUS、UNS など |

| 厚さ | 0.8-36mm または カスタマイズ |

| 幅 | 650-2000mm または カスタマイズ |

| 長さ | 0.8-6 m または カスタマイズ |

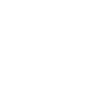

| 表面 | ミル仕上げ、研磨、光沢、オイル塗布、ヘアライン、ブラシ仕上げ、ミラー仕上げ、サンドブラスト、または必要に応じた仕上げ。 |

| 証明書 | CE、ISO、SGS、など |

| 最小発注数量 | 6 Ton |

| 納期 | 通常は7日間ですが、数量によって異なります。 |

| パッケージ | 輸出用標準パッケージ:木箱で束ねられ、あらゆる種類の輸送に対応可能、または要求に応じたもの |

| 適用 | タービンブレード、ガイドヴァン、タービンディスク、高圧コンプレッサーディスク、機械製造および燃焼室など、航空、海軍、産業用ガスタービンの製造に使用される高温部品 |

| DIN/EN | UNS NO | 通称 | 素材 | |

| 1 | 2.4060 | N02000 | ニッケル200 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.1C |

| 2 | 2.4601 | NO2201 | ニッケル201 | 99Ni-0.15Fe-0.2Mn-0.1Si-0.1Cu-0.01C |

| 3 | 2.4050 | N02270 | ニッケル270 | 99.9Ni-0.02Fe-0.001Mn-0.002Si-0.005Cu- 0.01C |

| 4 | 1.4980 | S66286 | INCOLOY合金 A286 | 25Ni-15Cr-1.5Mo-2Ti-1Mg-0.03C |

| 5 | N08367 | INCOLOY合金 25- 6HN |

25Ni-20Cr-6.3モ-0.25Cu-0.2N-0.01P-0.05S- 0.01C |

|

| 6 | 1.4529 | N08926 | INCOLOY合金 25- 6モ |

25Ni-20Cr-6.5モ-1Cu-0.2N-1.0Mg-0.01P- 0.005S-0.01C |

| 7 | 2.4460 | N08020 | INCOLOY合金20 | 36Ni-21Cr-3.5Cu2.5Mo-1Mn-0.01C |

| 8 | 1.4563 | N08028 | INCOLOY合金28 | 32Ni-27Cr-3.5Mo-1Cu-0.01C |

| 9 | 1.4886 | N08330 | INCOLOY合金330 | 35Ni-18Cr-2Mg-1SI-0.03C |

| 10 | 1.4876 | N08800 | INCOLOY合金800 | 32Ni-21Cr-0.3~1.2(Al+Ti)0.02C |

| 11 | 1.4876 | N08810 | INCOLOY合金 800H | 32Ni-21Cr-0.3~1.2(Al+Ti)0.08C |

| 12 | 2.4858 | N08825 | INCOLOY合金 825 | 42Ni-21Cr-3Mo-2Cu-0.8Ti-0.1AI-0.02C |

| 13 | 2.4816 | N06600 | インコネル 600 INCOLOY合金 600 |

72Ni-151Cr-8Fr-0.2Cu-0.02C |

| 14 | 2.4851 | N06601 | インコネル601 INCOLOY合金 601 |

60Ni-22Cr-1.2Al-0.02C |

| 15 | 2.4856 | N06625 | インコネル 625 INCOLOY合金 625 |

58Ni-21Cr-9Mo-3.5Nb-1CO-0.02C |

| 16 | 2.4856 | N06626 | インコネル 600LCF インコロイ合金 625LCF |

58Ni-21Cr-9Mo-3.5Nb-1CO-0.02C |

| 17 | 2.4606 | N06686 | インコネル 686 インコロイ 合金 686 |

57Ni-21Cr-16Mo-4W-0.01C |

| 18 | 2.4642 | N06690 | Inconel 690 インコロイ 合金 690 |

58Ni-30Cr-9Fe-0.2Cu-0.02C |

| 19 | 2.4668 | N0778 | インコネル 718 INCOLOY Alloy 718 |

52ニッケル-19クロム-5ニオブ-3モリブデン-1チタン-0.6アルミニウム-0.02炭素 |

| 20 | 2.4669 | N07750 | インコネルX750 INCOLOY Alloy 750 |

70ニッケル-15クロム-6鉄-2.5チタン-0.06アルミニウム-1ニオブ-0.02炭素 |

| 21 | 2.4360 | N04400 | Monel400 | 63ニッケル-32銅-1鉄-0.1炭素 |

| 22 | 2.4375 | N05500 | MONEL K-500 | 63ニッケル-30クロム-1鉄-3アルミニウム-0.6チタン-0.1炭素 |

| 23 | 2.4819 | N10276 | ハステロイ C-276 | 57ニッケル-16モリブデン-16クロム-5鉄-4タングステン-2.5コバルト-1マンガン-0.35バナジウム- 0.08Si-0.01C |

| 24 | 2.4610 | N06455 | ハステロイ C-4 | 65Ni-16Cr-16Mo-0.7Ti-3Fe-2Co-1Mn-0.08Si- 0.01C |

| 25 | 2.4602 | N06022 | ハステロイC-22 | 56Ni-22Cr-13Mo-3Fe-2.5Co-0.5Mn-0.35V- 0.08Si-0.01C |

| 26 | 2.4675 | N06200 | ハステロイ C-2000 | 59Ni-23Cr-16Mo-1.6Cu-0.08Si-0.01C |

| 27 | 2.4665 | N06002 | ハステロイX | 47Ni-22Cr-18Fe-9Mo-1.5Co-0.6W-0.1C-1mn- 1Si-0.008B |

| 28 | 2.4617 | N10665 | ハステロイB-2 | 69Ni-28Mo-0.5Cr-1.8Fe-3W-1.0Co-1.0Mn- 0.01C |

| 29 | 2.4660 | N10675 | ハステロイ B-3 | 65Ni-28.5Mo-1.5Cr-1.5Fe-3W-3Co-3Mn-0.01C |

| 30 | N06030 | ハステロイ G-30 | 43Ni-30Cr-15Fe-5.5Mo-2.5W-5Co-2Cu-1.5Mn- 0.03C |

|

| 31 | N06035 | ハステロイ G-35 | 58Ni-33Cr-8Mo-2Fe-0.6Si-0.3Cu-0.03C | |

| 32 | 1.4562 | N08031 | ニクロファー hMo31 | 31Ni-27Cr-6.5Mo-1.2Cu-2mn-0.01C |

| 33 | 2.4605 | N06059 | ニクロファー hMo59 | 59Ni-23Cr-16Mo-1.0Fe-0.01C |

製品紹介

グレード9チタン プレート 良好な強度と靭性があり、高温高圧条件下でも安定した性能を維持でき、航空宇宙および航空エンジンなどの分野に適しています。 さらに、グレード9チタン板は優れた耐食性を持ち、海水や塩水などの腐食性媒体の浸食に抵抗できるため、海洋工学や化学装置で広く使用されています。また、グレード9チタン合金は優れた溶接性があり、通常の溶接、アーク溶接、レーザー溶接などのプロセスに適しており、製造過程で高い塑性と加工性を発揮します。最後に、グレード9チタンは密度が低く、多くの他の金属よりも軽いため、軽量化設計が必要な部品において有利です。グレード9チタン板は、航空宇宙、海洋工学、化学装置などの分野で広く使用されています。

製品の特徴

特徴:

①異なるグレード

ステンレス鋼には異なるグレードがあり、それぞれ異なる硬さ、熱可塑性、塑性、溶接性に対応しています。もし理解できない場合、要件を教えていただければ結構です。

②異なる表面仕上げ

ステンレス鋼は異なる表面仕上げをカスタマイズでき、異なる表面仕上げには異なる用途があります。例えば、8Kミラーは一般的に装飾用に使われます。

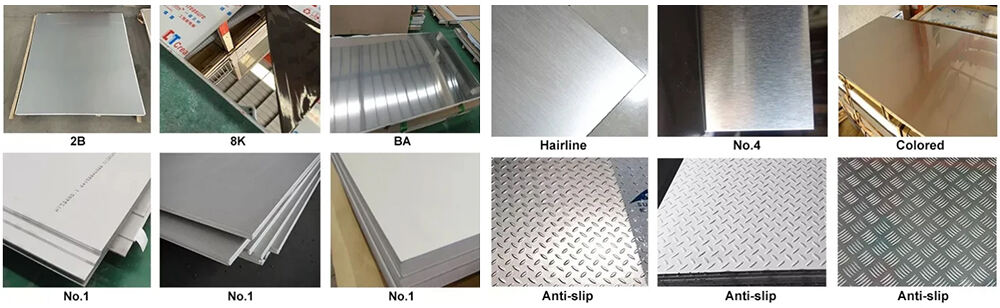

③高品質

私たちはこの業界で30年以上の経験があり、ステンレス鋼の原材料に関するあらゆる需要にお応えできると確信しています。

私たちは厳格な検出システムを持ち、三方検出をサポートしています

適用

ニッケル合金は次の産業で使用できます:

1. 熱処理工業。例えば、炉ローラー、ベル式炉、および退火炉などがあります。2. 焼成炉。例えば、高性能ルビーの焼成、フェロクロム合金を生産するためのクロマイトの焼成、または石油化学工業で使用される触媒としてのニッケルの回収に使用されます。3. 化学および石油化学工業で、新しい蒸気裂化ナフサ炉を準備して水素を生産するために使用されます。4. 自動化装置。例えば、触媒支持システム、スパークプラグなどがあります。5. 核工業用の清掃設備、例えば核廃棄物の除去など。6. 鉄工業。例えば、チタンスポンジを生産するために鉄鉱石の直接還元プロセスなどがあります。

包装と配送

パッケージ: 3重の包装です。中身はクラフト紙、真ん中は水プラスチックフィルム、外側は鋼帯でロックされたGI鋼板で覆われており、内側にはコイルスリーブが付いています。

輸送: 私たちは多くの経験豊富な船会社と長期的な協力をしており、あなたのために最も適切な輸送手段を見つけます。

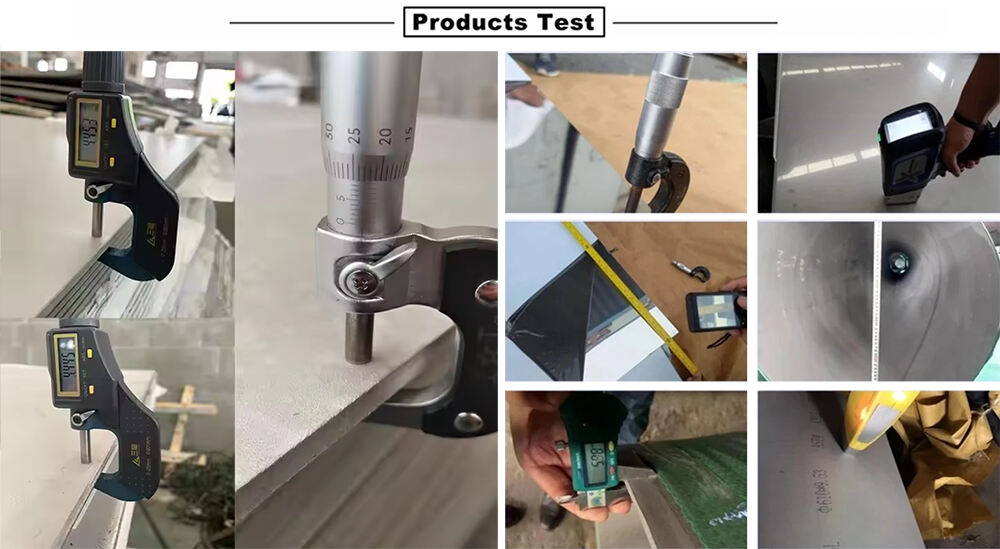

顧客のフィードバック

FAQ

Q: 商品を如期納品できますか?

A:はい,私たちは最高の品質の製品と間に合う配達を提供することを約束します.正直は当社の原則です.

Q: サンプルを用意していますか? 無料ですか?

A: サンプルは無料で提供できますが、配送業者の送料はお客様のご負担となります。

Q: 第三者検査を受け入れますか?

A: はい、絶対に受け入れます。

Q: 商品の保証は?

A: 各製品は認定された工場で製造され、runhai国の品質管理/QC標準に基づいて一つずつ検査されます。また、品質を保証するために顧客に対して保証書も発行できます。

Q: どのようにして貴社を信頼すればよいのでしょうか?

A: 当社は長年鉄鋼事業を専門としており、本社は山東省済南にあります。あらゆる方法で調査することを歓迎します。ぜひ、お支払いを保証できる貿易保証付きの注文を行ってください。

Q: できるだけ早く見積もりを入手するにはどうすればよいですか?

A: イメールとファックスは24時間以内に確認されます。同時に、Facebook、Skype、Wechat、WhatsAppは24時間オンラインです。ご要件と注文情報、仕様(鋼種、サイズ、数量、到着港)を送ってください。最適な価格をすぐにご提示いたします。

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN