Baja H-Beam adalah material yang sangat berguna yang sering digunakan dalam konstruksi. Dikenal karena kekuatannya dan mampu menopang beban berat tanpa patah. Dalam artikel ini, kami menjelaskan lebih lanjut tentang baja H-Beam, bagaimana diproduksi, di mana digunakan, serta beberapa kelebihan dan kekurangannya. Selanjutnya, kita akan melihat mengapa Anda mungkin ingin memperhatikan hal-hal seperti apa yang terjadi dengan baja H-Beam di masa depan, dan jika iya, bagaimana caranya?

Apa itu Baja H-Beam?

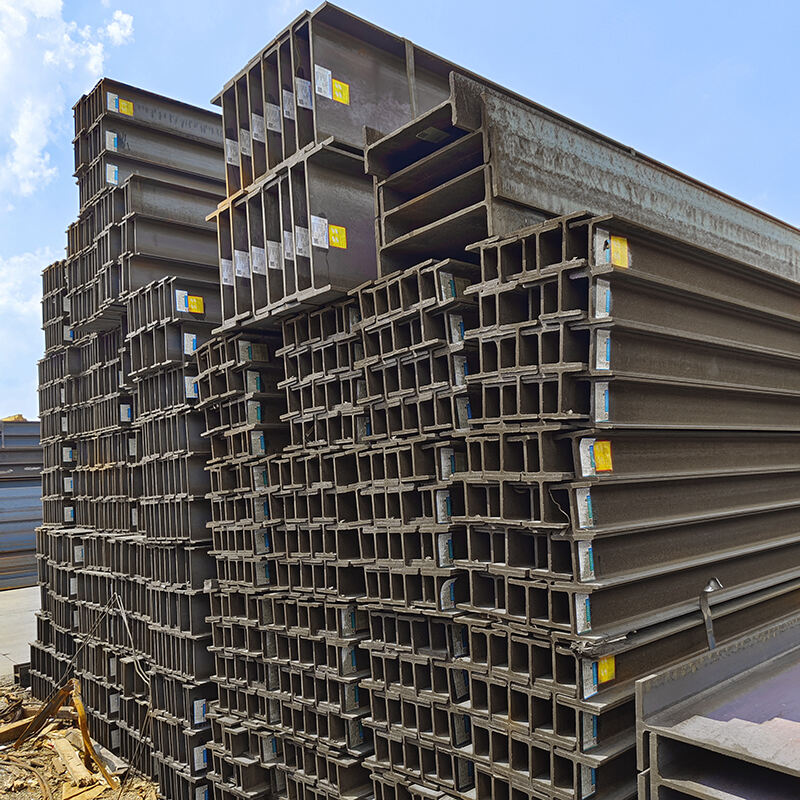

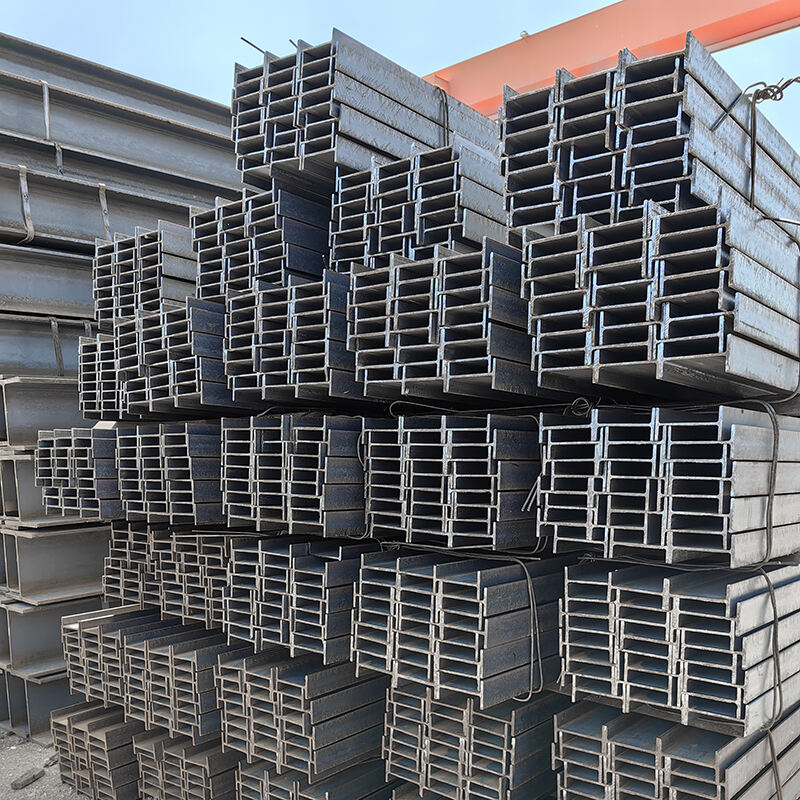

Baja H-Beam adalah jenis baja yang dibuat dengan mencampurkan karbon dengan bahan lainnya. Ini memiliki bentuk unik yang membuatnya sangat kokoh dan kuat. Baja H-Beam terdiri dari bagian lebar di atas dan bawah (juga dikenal sebagai flensa) dengan bagian yang lebih tipis di tengah. Nah, karena terdiri dari segitiga dan segiempat, ia mampu dengan mudah menopang beban besar, yang membuatnya sangat menguntungkan untuk membuat struktur yang kuat.

Baja berbentuk H memiliki fitur lain yang sangat penting, yaitu lebih ringan dibandingkan beberapa jenis balok baja lainnya, namun beban berat dapat dipikul dengan mudah. Distribusi berat baja H di seluruh balok. Dengan kata lain, penempatan ini berarti berat tidak terpusat di satu tempat, yang mengurangi tekanan pada balok sehingga membuatnya kurang mungkin untuk bengkok atau patah.

Bagaimana Baja H Dibuat?

Baja H diproduksi melalui proses pengerolan panas. Proses ini dimulai dengan blok baja padat besar yang dikenal sebagai ingot. Langkah pertama dalam memproduksi baja H adalah memanaskan ingot baja hingga suhu yang sangat tinggi. Ketika baja panas, ia menjadi lunak dan mudah dibentuk.

Baja H dibuat melalui serangkaian proses.

Pembuatan Baja: Proses pembuatan baja adalah proses yang panjang dan rinci yang dilakukan menggunakan bagian-bagian baja. Proses ini dikenal untuk melunakkan baja.

Penggilingan Panas: Ketika baja masih panas, ia digilas menjadi profil balok H oleh pabrik penggilingan panas. Mesin ini membentuk baja saat masih panas.

Penyejukan dan Pemotongan Balok, setelah dibentuk, didinginkan. Setelah mendingin, balok tersebut dipotong ke ukuran spesifik yang diperlukan untuk berbagai proyek konstruksi.

Dimana Baja Balok H Digunakan?

Baja balok H digunakan secara luas dalam pembangunan banyak tempat, termasuk lokasi konstruksi gedung dan jenis struktur lainnya. Pipa baja tahan karat ini biasanya digunakan untuk gedung-gedung besar, jembatan, dan infrastruktur penting lainnya. Baja balok H juga digunakan untuk memproduksi mesin-mesin besar seperti derek dan kapal, selain untuk konstruksi.

Sebagian besar orang suka menggunakan baja H-Beam karena kemampuan menahan beban yang tinggi, yaitu, dapat menahan banyak berat. Baja H-Beam juga dihargai karena keawetannya, yaitu kemampuan untuk menahan aus seiring berjalannya waktu. Baja H-Beam bekerja dengan sempurna, baik pada hari yang panas terik maupun pada hari yang badai, ini adalah solusi teknologi yang tahan lama bagi para pembangun.

Kelebihan dan Kekurangan Baja H-Beam

Seperti bahan apa pun, ada keuntungan dan kerugian dari baja H-Beam.

Kapasitas Menahan Beban yang Luar Biasa: H-Beam memiliki kapasitas menahan beban yang tinggi, yang menjadi alasan mengapa mereka secara luas digunakan dalam struktur besar.

KUAT & PENDUKUNG: Didesain untuk bertahan selama bertahun-tahun, bahkan dalam situasi yang sulit.

Ringan: Baja H-Beam lebih ringan daripada jenis balok lainnya, mengurangi biaya transportasi dan pemasangan.

Mudah Dipasang: Baja H-Beam cukup sederhana bagi pekerja untuk ditempatkan, sehingga menghemat waktu selama konstruksi.

Hal-hal buruk:

Biaya Awal Tinggi: Baja H-Beam memiliki biaya awal yang lebih tinggi dibandingkan balok tradisional, yang dapat menjadi hambatan bagi anggaran beberapa proyek.

Rentan terhadap Korosi: Baja dapat mengalami korosi seiring waktu jika tidak dirawat dengan baik, dan hal ini akan mengurangi integritas strukturalnya juga.

Masa Depan Baja H-Beam

Penggunaan komersial teknologi baja H-Beam juga telah sangat umum. Untuk menyesuaikan sifat baja H-Beam, banyak insinyur dan ilmuwan sudah bekerja keras pada tugas tersebut.

Selain itu, semakin diperlukan untuk membuat baja H-Beam mild lebih signifikan bagi lingkungan. Peneliti sedang mempelajari teknik produksi untuk baja H-Beam yang mungkin lebih ramah lingkungan, seperti dengan menggunakan bahan daur ulang atau meminimalkan konsumsi energi dalam proses manufaktur.

Baja H-Beam ST/PANAMA adalah salah satu material yang paling banyak digunakan dalam industri konstruksi. Baja ini memberikan kekuatan dan dukungan besar untuk beban yang sangat berat, itulah sebabnya ia menjadi sahabat para pembangun. Baja H-Beam sendiri dibuat dengan memanaskan baja dan menggilirkannya menjadi bentuk H, yang memberikan sifat-sifat uniknya. Meskipun memiliki kekuatan dan kemudahan pemasangan, baja ini juga memiliki beberapa kelemahan berupa biaya dan kemungkinan berkarat. Iterasi berikutnya dari teknologi baja H-Beam sangat menarik, dan orang-orang berusaha untuk meningkatkan kualitas dan keberlanjutannya.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN