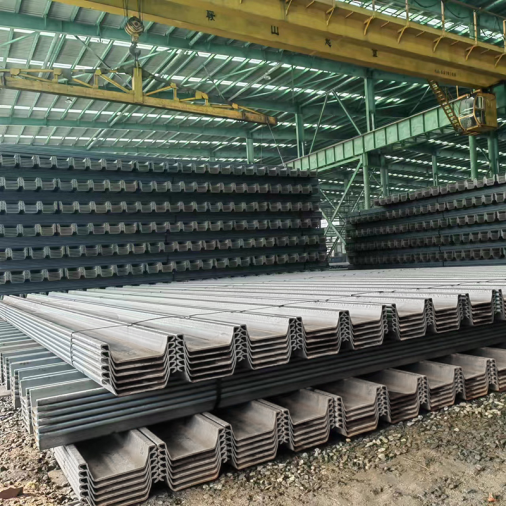

Sheet piles are made on specialized machines and are made by skilled labor, so the process is quite interesting and exciting. Runhai is steel sheet piles manufacturer. They put in a lot of effort to get their products strong, rugged, and durable with long-lasting usage. This means that you can be confident that their products do what they should do when you purchase them.

How Steel Sheet Piles Are Created

01 The choice of High quality materials Runhai selects from the finest materials to manufacture the horganyzott acéllemez piles. So that their customers are happy and satisfied, they only use the best quality materials in order to ensure that. This option matters a lot since the quality of the materials used directly relates to how durable the final product will be. The materials (which can be usually powdered metals) are heated until they are molten (turn into liquid form). Then this melted steel is poured into a “mold”, where it cools down into long, flat pieces.

Once the pieces cool off, they are cut in smaller pieces. It’s similar to slicing a big cake! So we slice the big rolls into smaller pieces, and run them through a rolling machine which flattens them out to become sheets. Cutting and shaping these sheets just so takes great care, so they fit the right size, and they sit at the right thickness. Inaccurate cutting of the sheets can cause the sheets not to fit properly into the construction.

Steel Sheet Pile Production: Machinery and Manpower

A gyártás folyamata acél csatorna sheet piles requires specific machinery and trained labour familiar with the operation of the machines. Automatic 9 production lines including high-end automatic production machines. These machines were built to lift heavy steel and do precision work.

The most important thing is we are able to do this in our own company. The subjects are trained at their jobs, and they do so very delicately. They monitor the machines to ensure they are working properly and efficiently. In the case of problems, the workers can easily correct them and hence prevent any error.

A minőség-ellenőrzés jelentősége

Making steel sheet piles requires a great deal of quality control. Runhai goes through a lot of time and labor to verify that our products remain robust and reliable. We want to ensure every single product we produce lives up to our standards.

Our quality control team oversee the entire process end to end. They test the ingredients to ensure they're high quality, observe the machines to check the machinery is running properly, and perform ultimate tests on the end products to make certain everything is spot on. Meticulous verification allows us to identify any issues early on to ensure step-by-step rectification before the products reach our customers.

Forming Steel Sheet Piles in Unique Ways

Steel sheet piles can be formed in many shapes and configurations. From Runhai consider using the following methods to ensure your products are of the highest quality. By using these methods, we can build products that are ace and robust, something that our customers can rely on.

This technique is known as cold forming. That means we don’t heat up the steel sheets at all and instead bend them and shape them. This method helps us to obtain quality products with similar steel properties withers. This is significant as we would like to ensure our products are durable enough to handle all range of heavy usage on construction projects.

How We Make Strong Steel Sheet Piles

To produce solid and dependable szögacél sheet piles is a thorough process, which needs experienced workers and modern machines. At Runhai, we are dedicated to ensuring that our products are of the utmost quality, manufactured according to specific industry rules and guidelines. We know our customers require products that can perform under duress.

Every element of our manufacturing process utilizes the utmost attention to detail, quality control, and only the finest raw materials. We would like to give to our customers the strong and reliable and long-term lasting products in their projects.

To put in a nut shell, a skilled manpower, advanced machinery and strict quality checks are required to manufacture steel sheet piling. At Runhai, we stand by the quality of our products and want to make sure customers are only getting the best. We hope you now know more about how we produce steel sheet piles and our commitment to quality! You can begin to understand how much goes into making the steel you see in construction around you.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN