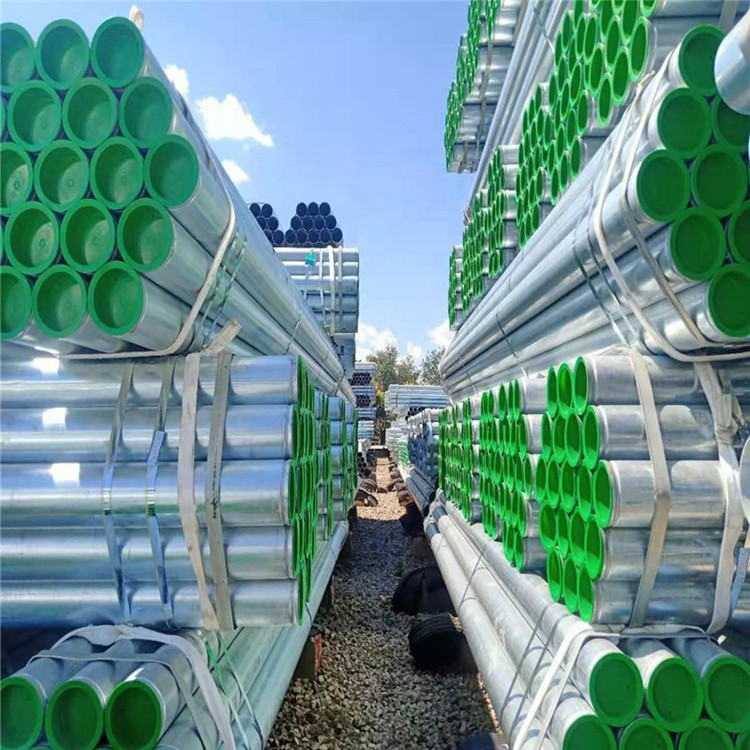

Amazing Galvanized Steel Tube For You Heavy-Duty Projects

Galvanized steel tubes are unrivaled as far as construction materials go for larger scale projects. These qualities have revolutionized the construction industry and could provide your project with an unrivalled level of innovation, safety features, adaptability and lifespan if you decide to use these metals. This article is going to discuss the massive pros, uses and a more top notch of galvanized steel tube by Runhai.

Benefits of Galvanized Steel Tubes

There are a number of benefits that come with using galvanized steel tubes. To begin, these tubes are coated with an anti-rust and corrosion coat which allows them to last longer. This protective care that also works for preventing rusting and wear, in harmful UV rays all through severe conditions that can damage your car. In addition, galvanized steel pipe tube come with excellent strength and durability to support heavy loads effectively so are the perfect choice for enterprise heavy applications.

Galvanized steel Tubes innovation

It represents a revolutionary advancement in the production of steel tubes, carrying with it qualities that supersede those found in normal steel tubing. In contrast to standard steel tubes, these metals are immerging with zinc material initiates a special process that makes each of this type even stronger than the former and more resistant injuries. The zinc layer also serves as a protective coating that prevents fuel or brake fluid from deteriorating the tubing material due to contact with chemicals, salt and moisture.

Galvanized Steel Pipes Safety Features

In the construction industry, safety is a top priority means ensure each structure meets or exceeds high levels of security. The Galvanized steel tubes comes with safety profile due to the inbuilt characteristic of materials used. Rubber bushings are the resilient bearings that support these tubes with unmatched tensile qualities to avoid galvanized seamless steel pipe collapsing because of excess load. They are noncombustible when covered with zinc, which ensures that they release no toxic gases if a fire happens to break out and do not ignite as quickly (providing safety within the construction industry).

Uses of Galvanized Steel Tubes

Applications of Galvanized steel tubes are varied across industries such as Construction, Mining and Manufacturing. The tubes are used to build stair cases, in the making of scaffolding and also establishing skeleton frames for buildings or bridges. They are essential in the construction of conveyance systems and piping for transporting ore mines as well ventilation methods used within mining. Moreover, these galvanized steel tubes find an essential application in the manufacturing verticals for welding of automobiles and heavy machinery due to their ability to withstand harsh environments.

Types of Galvanized steel tubes with quality standards

The galvanized steel tubes are the opposite regarding quality. These tubes are made from best-in-class steel that ensures greater strength and toughness than other metals in the market. Furthermore, an additional rust and corrosion-resistant coating means that they will not be weakened by chemicals or environmental factors so they can hold their shape for longer.

Using Galvanized Steel Pipes

You found the process which could involve making use of galvanized steel tubes straightforward. To begin, track the appropriate size and length of tubing for your project Next, use a saw or pipe cutter to cut the tubes into desired lengths. Clean and remove manmade material on the ends of tubes before assembly. The tubes are then joined together by precision welding molten with MIG welders, which is one of the most commonly used welding techniques that produces strong and seamless connections perfect for rugged construction projects.

Galvanized Steel Tube Maintenance

Best maintenance is required to find the best in effectiveness of galvanized steel tubes. Although these tubes need only little maintenance, they will still have to be cleaned and regularly inspected for wear. Belonging to the incredibly rust- and corrosion-resistant class, they really need nothing more than some light water washing with mild soap. Furthermore, correct storage and handling are essential for extending the life of tubing with dry storage in an environment free from rusting, moisture or chemicals that could otherwise damage these tubes.

In Summary

However, galvanized steel tubes are the ideal solution for construction and manufacturing projects which require a durable and trusted material. The best of all is that these tubes bring along a plethora of advantages such as: Longevity, Strength, Security, High quality. They are advanced, safe and customer friendly which makes them perfect for heavy projects. When it comes to industrial application, galvanized steel tubing is versatile and potentially brings relevant benefits for any construction team. These tubes have low maintenance requirements and are likely to last for many years, making them a cost-effective solution especially when used in construction jobs. Choose and galvanized steel ferrets to your next project, safe in the knowledge that you are using a product of superior quality.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN