Just how are spiral Pipes which welded Produced?

Introduction

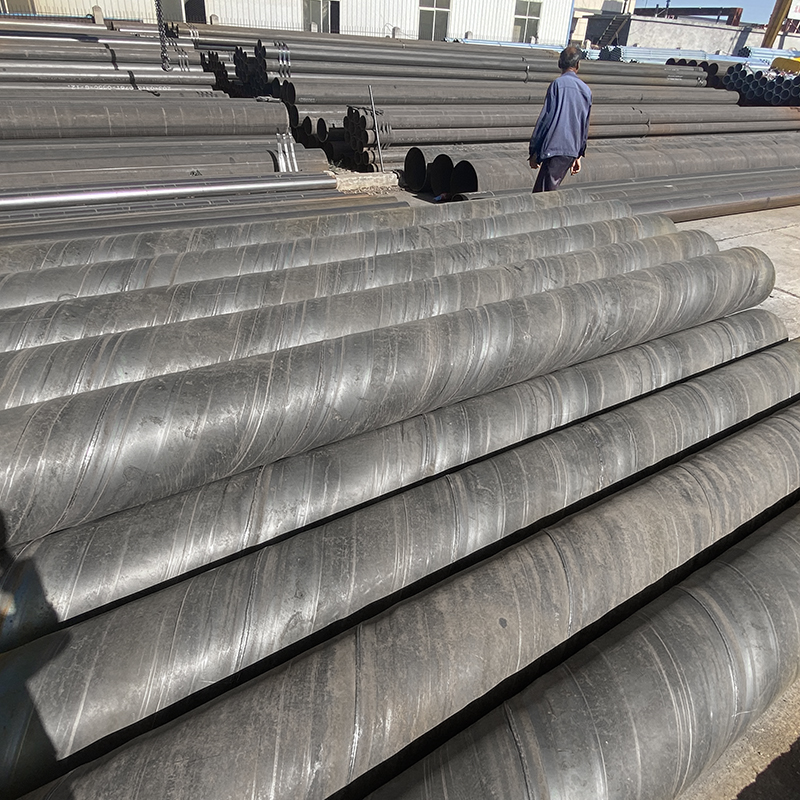

In the wide world of pipelines, spiral welded pipelines are building a splash which big. These runhai pipelines being unique a variety of advantages that other pipelines just can’t match. Spiral welded pipelines are manufactured employing a procedure that is unique involves rolling metal strips into long pipes being then welded together. This creates a powerful, durable pipeline which ideal for a number of applications.

Benefits of Spiral Welded Pipelines

There are lots of advantageous assets to making use of spiral pipelines being welded. To begin with, they' re extremely strong. These pipelines are manufactured utilizing top-notch metal that's rolled and welded in a pattern that's spiral. This produces a pipeline which stronger than conventional pipelines, that are typically made employing a seam that's directly. Also, spiral pipelines which are welded more resistant to breaking and breaking, making them more dependable and safer to utilize.

Innovation within the manufacturing of Spiral Welded pipelines

The manufacturing of spiral welded pipelines actually procedure that is very revolutionary. It needs gear that's specialized skilled employees who can create top-quality pipelines with accuracy and precision. One of the primary innovations into the manufacturing of those pipelines may be the usage of robotic welding devices, that are in a position to weld the pipelines with amazing persistence and precision.

Safety and Use of Spiral Welded Pipes

Spiral pipelines being welded extremely safe to utilize. These pipelines are created to withstand a number of conditions and will be utilized in a selection of applications. They' re widely used in fuel and oil industry, plus in water and sewage systems. They' re additionally found in the carbon steel pipe for construction industry, in which they' re usually utilized as structural aids for structures along with other structures.

Utilizing Welded that's spiral pipelines

Utilizing spiral pipelines which are welded quite simple. These pipelines may be used in a number of applications, and they' re typically employed for transporting liquids and gases from location to a different. When utilizing these pipelines, it is vital that you proceed with the manufacturer’s directions. Also, appropriate installation and upkeep are fundamental to making sure the pipelines stay in good shape and continue steadily to work precisely.

Service and Quality of Spiral Welded Pipelines

With regards to spiral pipelines being welded quality is key. These spiral steel pipe are created to final for a long time, and they' re usually utilized in applications in which failure isn't a choice. That’s why it is crucial that you select a provider which reputable provides top-quality pipelines that meet your unique requirements. Furthermore, it is vital that you decide on a provider who are able to offer solution which dependable help through the entire life of this pipelines.

Application of Spiral Welded Pipelines

Spiral welded pipelines are employed in many different applications, including coal and oil pipelines, water and sewage systems, and structural aids. They' re additionally found in the construction of bridges, tunnels, along with other infrastructure tasks. Whether you are taking spiral steel pipe of a task which large-scale a little construction work, spiral welded pipelines can be an exemplary option for an array of applications.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN