RUNHAI STEEL

Your Reliable Steel SupplierRunhai steel is not only a professional steel supplier, but also your trustworthy partner in China. We ensure quality and quantity, provide material certificates, and will refund if the products are not qualified, so please be assured the purchase. Regarding long-term cooperation or large orders, you can contact us for additional discounts.

Enjoy Bulk Order DiscountsFOUR REASONS TOCHOOSE US

-

AAA Level

Credit Steel Supplier

Gold Certified Merchant

-

20+

Have our own R&D team

Large inventory Warehouses

-

Support

Three-party Inspection

-

Large Order

Preferential Policies

Get in touch

Product Video

Product Parameter

| Product Name | T-Type Ductile Iron Pipe |

| Size |

Outside Diameter:98mm-1255mm Inside Diameter:80mm-1200mm Wall Thickness:6mm-153mm Length:6m,cut to 5.7m,or as required. |

| Grade | K9,K10,K11,K12,K9,K8,C25,C30,C40,etc. |

| Standard | ISO2531,EN545,EN598,etc |

| Surface | External bitumen coating, or as required. |

| Internal coating |

a). Portland cement mortar lining b).Sulphate Resistant cement mortar lining c).High-Aluminum cement mortar lining d).Fusion bonded epoxy coating e). Liquid epoxy paintingf). Black bitumen painting |

| External coating |

a).zinc+bitumen(70microns)painting b).Fusion bonded epoxy coating c).Zinc-aluminum alloy +liquid epoxy painting |

| Quality Control | 100% inspection + professional Lab test |

| Certification | ISO, CE, BSI, WRAS,SGS,etc |

| M0Q | 25 TONS |

| delivery time | Usually 7 days, depending on the quantity |

| Package | Standard export package (Bundled with steel belts or in bulk ), or as required. |

| Payment | T/T, L/C, Western Union, etc. |

| Application | Water supply project,drainage,sewage, irrigation, water pipeline, etc. |

| DN(mm) | DE(mm) | Wall Thickness (mm) |

WEIGHT OF SOCKET(kg) |

Total Weight (kg) |

||||

| K8 | K9 | K10 | 3.4 | K8 | K9 | K10 | ||

| 80 | 98 | 6.0 | 6.0 | 6.0 | 4.3 | 77.0 | 77.0 | 77.0 |

| 100 | 118 | 6.0 | 6.0 | 6.0 | 5.7 | 93.7 | 95.0 | 95.0 |

| 125 | 144 | 6.0 | 6.0 | 6.0 | 7.1 | 119.0 | 119.0 | 121.0 |

| 150 | 170 | 6.0 | 6.0 | 6.0 | 10.3 | 138.0 | 144.0 | 144.0 |

| 200 | 222 | 6.0 | 6.3 | 6.4 | 18.9 | 183.0 | 194.0 | 194.0 |

| 300 | 326 | 6.4 | 7.2 | 8.0 | 23.7 | 290.0 | 323.0 | 357.0 |

| 350 | 378 | 6.8 | 7.7 | 8.5 | 29.5 | 359.0 | 403.0 | 441.0 |

| 400 | 429 | 7,2 | 8.1 | 9.0 | 38.3 | 433.0 | 482.0 | 532.0 |

| 450 | 480 | 7.6 | 8.6 | 9.5 | 42.8 | 515.0 | 577.0 | 632.0 |

| 500 | 532 | 8.0 | 9.0 | 10.0 | 59.3 | 600.0 | 669.0 | 736.0 |

| 600 | 635 | 8.8 | 9.9 | 11.0 | 79.1 | 791.0 | 882.0 | 971.0 |

| 700 | 738 | 9.6 | 10.8 | 12.0 | 102.6 | 1009.0 | 1123.0 | 1237.0 |

| 800 | 842 | 10.4 | 11.7 | 13.0 | 129 | 1255.0 | 1394.0 | 1537.0 |

| 900 | 945 | 11.2 | 12.6 | 14.0 | 161.3 | 1521.0 | 1690.0 | 1863.0 |

| 1000 | 1048 | 12.0 | 13.5 | 15.0 | 237.7 | 1811.0 | 2017.0 | 2221.0 |

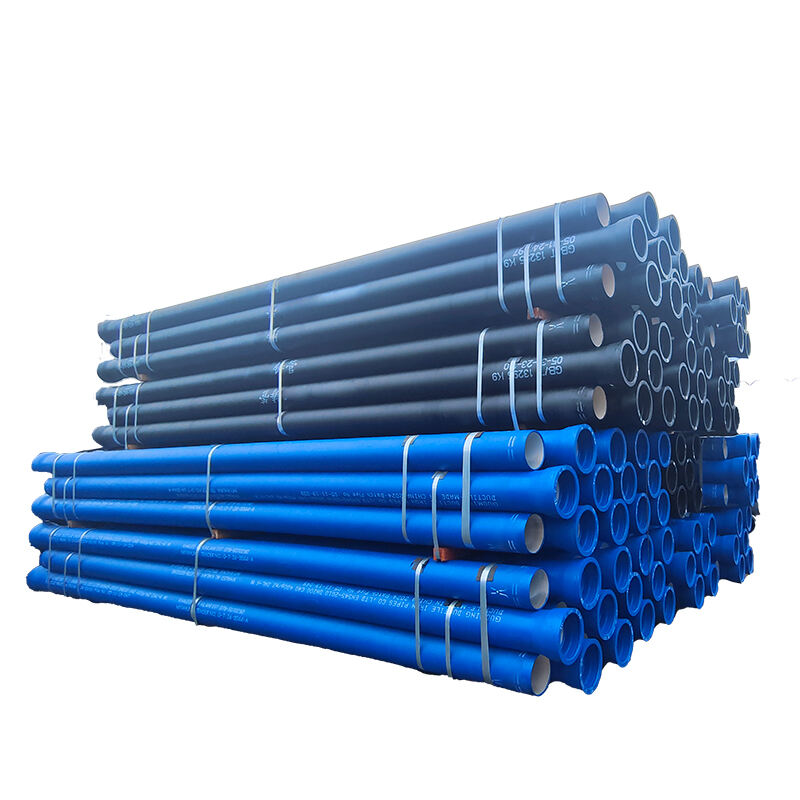

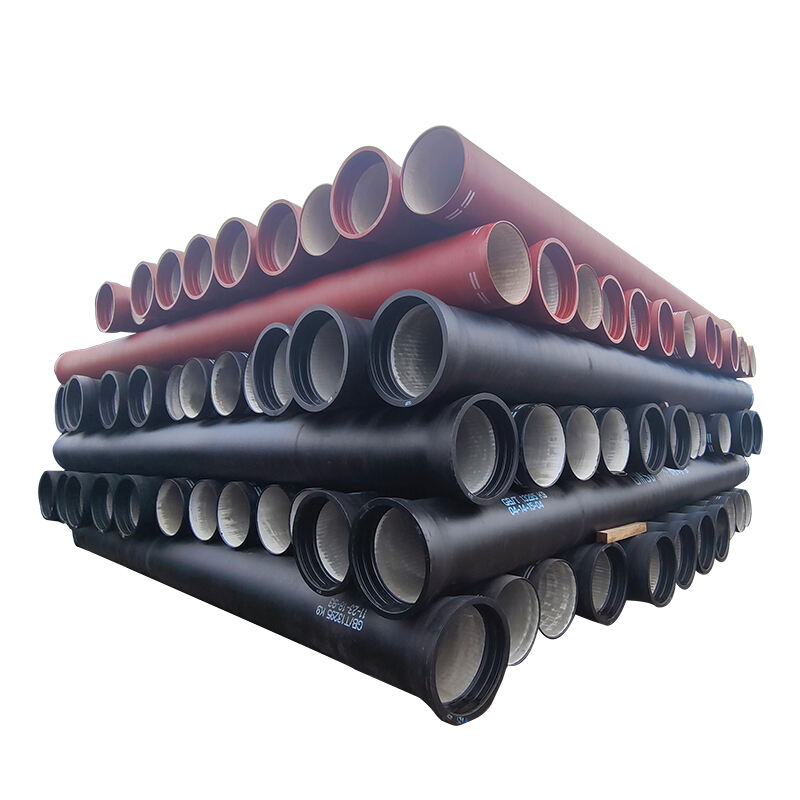

Product Show

Ductile iron pipes have long been a popular choice for the construction of water and wastewater pipelines due to their durability, strength, and ease of installation. Among the various types of ductile iron pipes available in the market, T-type ductile iron pipes stand out as a versatile and reliable option for various applications.

T-type ductile iron pipes are widely used in water supply networks, sewerage systems, and other industrial applications due to their superior performance and long service life. These pipes are known for their high resistance to pressure, corrosion, and abrasion, making them ideal for carrying water, sewage, and other fluids under various conditions.

One of the key features of T-type ductile iron pipes is their unique T-shaped joint design, which provides a strong and leak-proof connection between pipes. This design eliminates the need for extra fittings or connectors, reducing the risk of leakage and ensuring a smooth flow of fluids through the pipeline. The T-type joint also allows for easy and quick assembly, saving time and labor costs during installation.

Furthermore, T-type ductile iron pipes are cost-effective and environmentally friendly solutions for water and wastewater infrastructure projects. These pipes have a low maintenance requirement and can withstand harsh conditions without compromising their structural integrity. With proper installation and maintenance, T-type ductile iron pipes can last for several decades, providing a reliable and long-lasting solution for water and sewage conveyance.

In conclusion, T-type ductile iron pipes are a versatile and reliable choice for water supply, wastewater, and industrial applications. With their unique T-shaped joint design, high durability, and corrosion resistance, these pipes offer a cost-effective and efficient solution for pipeline projects. Whether used in water supply networks, sewerage systems, or industrial applications, T-type ductile iron pipes provide a reliable and long-lasting solution for fluid conveyance. Consider choosing T-type ductile iron pipes for your next pipeline project to experience the benefits of their superior performance and durability.

Product features

1.The performance of internal pressure resistance:Centrifugal ductile iron has the essence of iron and the performance of steel, so the ductile iron pipes have excellent security performance than pipes made from other materials. The designed working pressure is much higher than that of pipes made from other materials, the safty factor is pretty high, and the possible burst pressure is three times of the working pressure.

2.The performance of outer pressure resistance:The high pressure resistance can avoid the requirement of the pipe bed and protective cover, making the pipes laying rellable and economic.

3. Inner anti-corrosion layer:The inner layer of ductile iron pipes are centrifugally sprayed with cement mortar. Cement lining complies with the international standard ISO4179, ensuring the mortar strong and smooth. The motor coating will not fall off or foul, and its thickness is even ensuring the drinking water transferred by the pipes get good protection.

4.Protective coating:The zinc spraying of ductile iron pipes could protect the pipes proactively through the electrochemical effect of zinc and iron. With the high chiorinated resin paint, the pipes will get enhanced anti-corrosion protection. The surface zinc spraying of each pipe is not less than 130g/m², amd cpmplies with ISO8179 standard. We can also increase the zinc spraying thickness or spray zinc & aluminum alloy layer according to the customers' demand.

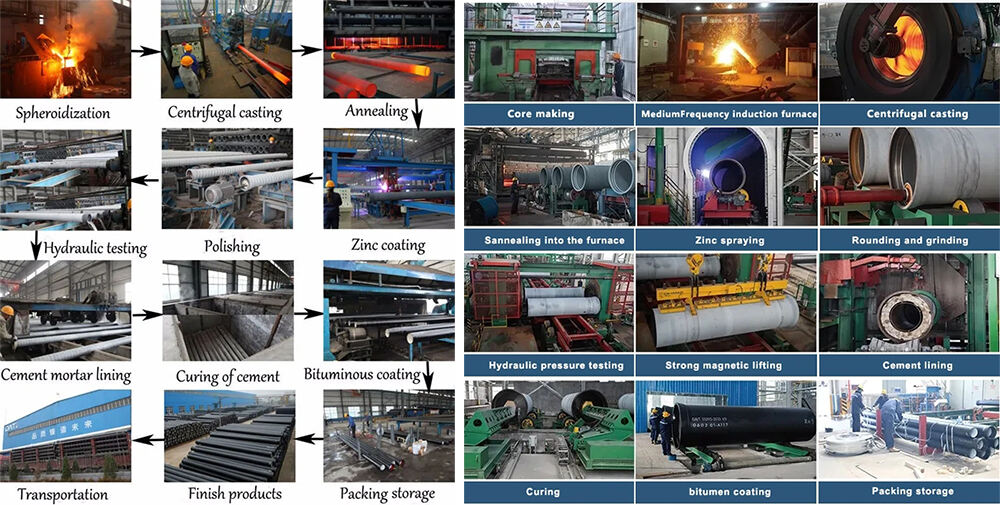

Ductile iron pipe manufacturing process:

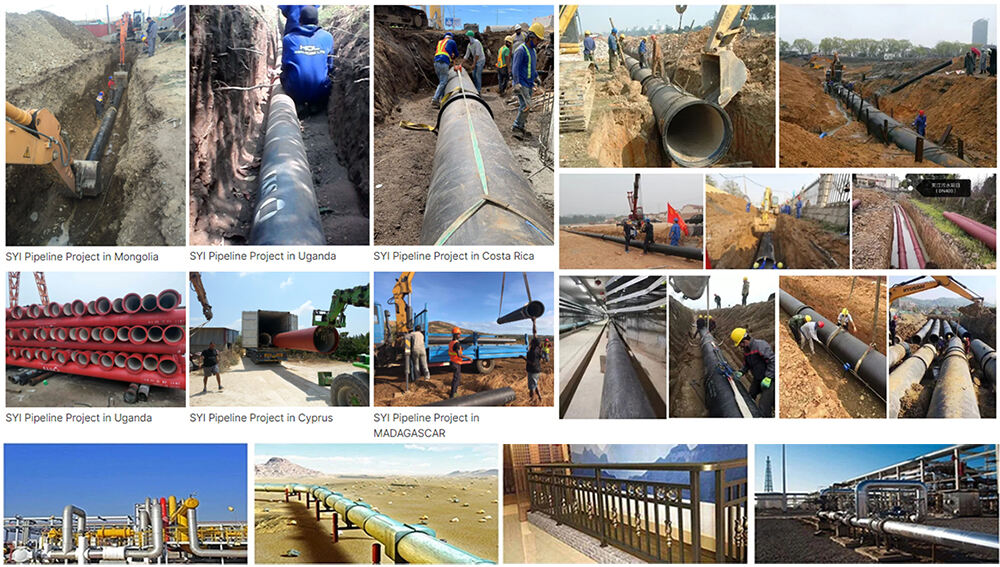

Application

1.Ductile iron pipes for water conveyance:

Product standards: BS EN545:2002, ISO2531:1998

1) Pipes are supplied in standard length of 5.5/6.0m, short length pipes as per respective standards can be supplied.

2) In addition to Class K9 pipes, we also supply K7, K8, K10 and K12 classes of pipe.

3) The thickness can be determined by the formula e=K (0.5+0.001DN)

4) PFA (allowable operating pressure) is the internal pressure, exclusive of surge, that a component can safely withstand in permanent service.

5) PMA (allowable maximum operating pressure) is the maximum internal pressure, including surge, that a component can withstand for a relatively short duration, when either fixed above ground level or laid and back filled underground in order to measure the integrity and leak tightness of the pipek.

2. Ductile iron pipes for sewerage application:

Product standard: BS EN598:2002

Quality checks at every stage of manufacturing:

1) Strict selection of raw material is an indispensable requirement to produce quality ductile iron pipes and fittings.

2) We produces liquid metal suited to manufacture ductile iron pipes. The liquid metal is further processed in induction furnaces.

It is then treated with magnesium for modularization and transferred to the centrifugal spun casting machines.

3) The pipes are heat treated, zinc coated, hydrostatically tested, tested, cement mortar lined and finished with a layer of bitumen coating.

4) The in process inspection and quality control at all points during the production cycle is strictly maintained and documented as ISO9001 quality systems.

Packing & Delivery

-

DN80-DN300: Usually by bundles;

-

DN350-DN2000: Usually by bulk;

-

During transportation, the pipes are fixed by timbers, blocks, nails & steel ropes with cushions at the side in possible moving

directions;

-

Bulk or containers for Shipping,shipment, and trucks or train for inland transport.

-

Can be packaged according to customer requirements

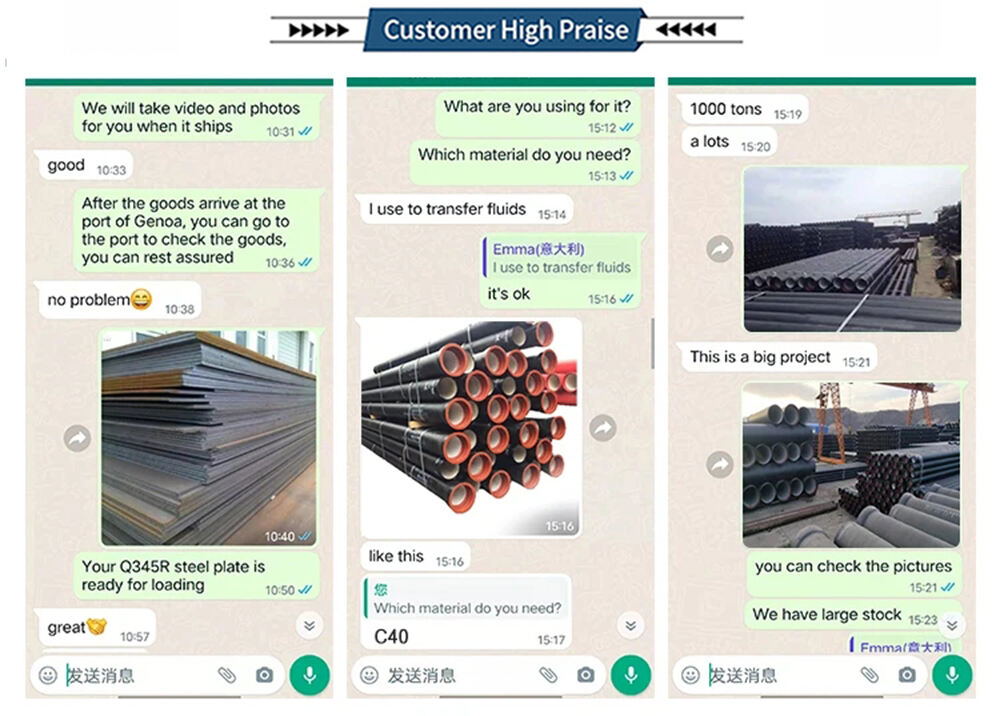

Customer Feedback

FAQ

Q: Will you delivery the goods on time?

A: Yes,we promise to provide best quality products and delivery on time .Honesty is our company's tenet.

Q: Do you provide samples ? is it free or extra ?

A: The sample could can provide for customer with free,but the courier freight will be covered by customer account.

Q: Do you accept the third party inspection?

A: Yes absolutely we accept.

Q: How could you guarantee your products?

A: Each piece of products is manufactured by certified workshops, inspected byRUNHAIpiece by piece according to national QA/QC standard. We also could issue the warranty to customer to guarantee the quality.

Q: How do we trust your company?

A: We specialise in steel business for years, headquarter locates in Jinan, Shandong province, you are welcome to investigate in any ways, by all means, you could place an order with trade assurance which could secure your payment.

Q: How can I get your quotation as soon as possible?

A: The email and fax will be checked within 24 hours,meanwhile,theFacebook,Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement and order information,specification(Steel grade,size,quantity,destination port),we will work out a best price soon.

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

LO

LO

MN

MN